After my Bad Casting Day, one thing on the to-do list was to tear down the mould because the type being cast had a lot of flash at some of the edges. Read more ›

A slightly better casting day

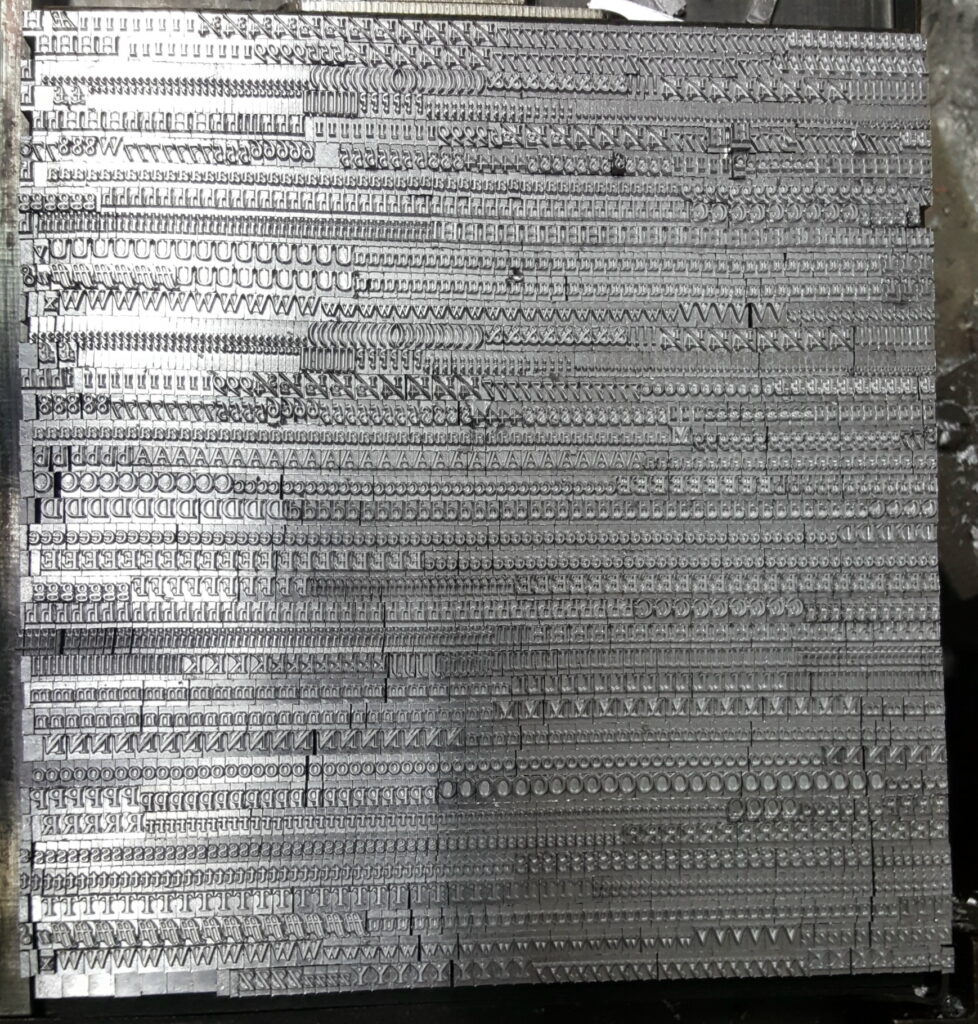

After the really bad casting day a few weeks ago, almost anything would be an improvement. I had taken steps to resolve some of the problems, and here is the result:

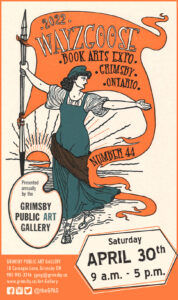

Wayzgoose is Back!

After a 2-year hiatus due to the pandemic, the Grimsby Wayzgoose Book Arts Fair will be returning this year, on Saturday April 30, 2022, from 9 a.m. to 5 p.m. at the Grimsby Public Art Gallery, 18 Carnegie Lane, Grimsby, Ontario.

After a 2-year hiatus due to the pandemic, the Grimsby Wayzgoose Book Arts Fair will be returning this year, on Saturday April 30, 2022, from 9 a.m. to 5 p.m. at the Grimsby Public Art Gallery, 18 Carnegie Lane, Grimsby, Ontario.

Although the number of exhibitors has been substantially reduced this year to allow for physical distancing, we’ll still have a table there selling handmade paper, marbling, bookbinding supplies, and other book arts items, along with a selection of books about the book arts.

As is traditional, even for the two missed years, there will be an Anthology produced containing contributions from many book artists including ourselves, although this will not be ready for distribution until later in the year.

For more information, please consult the Town of Grimsby’s web site, or the Gallery’s Facebook or Instagram pages.

(Updated 13/April/2022 to add the poster image)

A Bad Casting Day

Yesterday I made a try at casting a font of 12-point Caslon Old Style using composition mats and the computer interface for the caster. The results were less than stellar. A whole bunch of things went wrong: Read more ›

The results were less than stellar. A whole bunch of things went wrong: Read more ›

Thoughts on Making Lanston Matrix Blanks

There are times where it would be nice to be able to make my own Lanston-style display matrices to use on my Monotype Composition caster. Often I find that matrices made by other casting aficionados were made by cannibalizing a matrix from a surplus font. This has a few downsides: One is that the supply of such expendable matrices is finite; like real estate, they (Lanston) aren’t making any more. Another is that the original marking on the matrix are misleading if left in place, and sometimes do not leave enough room for new markings. Finally, such matrices can only be used for electrodepositing, not for engraving.

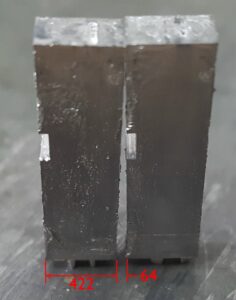

Relabeling Those Pesky Caslon Matrices

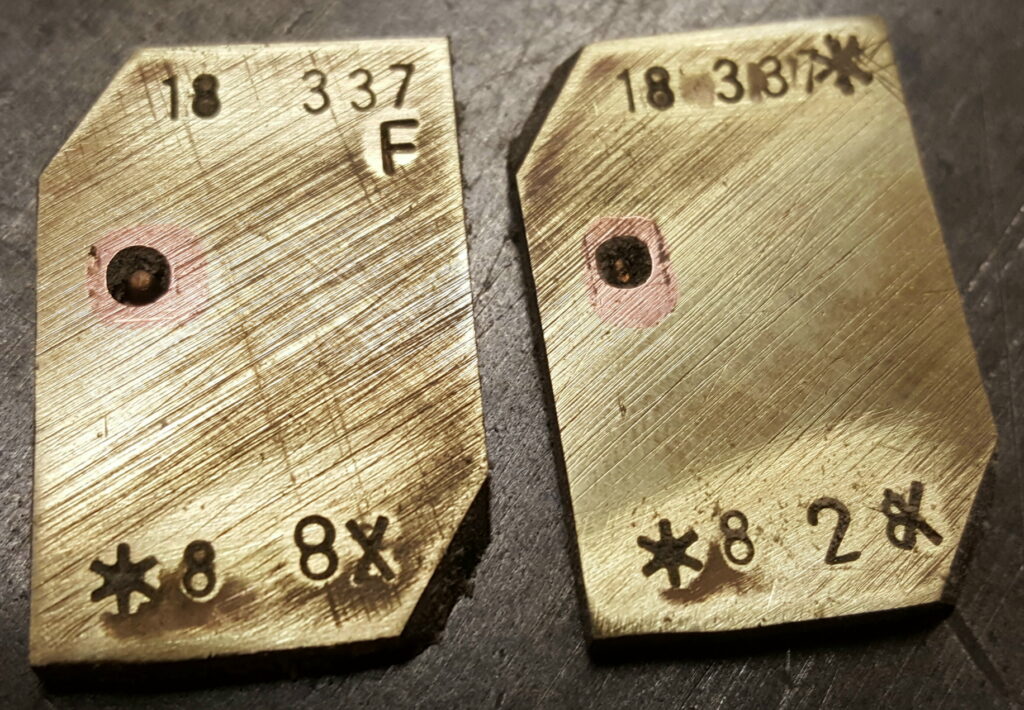

I recently found a pair of mis-labeled matrices in my set of 18-point Caslon Old Style, and although I could just leave a note in the storage box, I thought it would be better to just correct the markings on the matrices themselves.

Zero on the left, marked as the letter ‘o’, should have the ‘F’ mark and width *8 8, and the letter ‘o’ on the right, marked as the figure zero, should have no ‘F’ and width *8 2.

I have a set of 2mm (about 0.080″) alphanumeric punches, which I actually purchased for just this sort of work, and this would be my first use of them for this purpose.

One question was how I would obliterate the incorrect markings. The fancy way would be to mill off the marked edge, making the matrix resemble the stamped aluminum style of matrix, and put on a complete fresh set of markings. In this case there were only a couple of individual letters and digits to remove, and plenty of space nearby for the new markings, so I just opted to essentially scribble over them by punching them with an ‘X’ a few times.

Punching the markings raises the surrounding metal a bit and it it essential that any such raised area that is too near the letter itself be smoothed off so it does not impede proper seating of the matrix on the face of the mould. On these particular matrices I have enough room to keep the markings well away from this critical area, but I removed the raised parts anyway so the matrix would have a flat face overall. This also makes the markings easier to read, and it looks like I got the ‘8’ inverted. These punches are pretty small, so perhaps I’ll see if there are any orientation marks on their shank to avoid this in the future.

Punching the markings raises the surrounding metal a bit and it it essential that any such raised area that is too near the letter itself be smoothed off so it does not impede proper seating of the matrix on the face of the mould. On these particular matrices I have enough room to keep the markings well away from this critical area, but I removed the raised parts anyway so the matrix would have a flat face overall. This also makes the markings easier to read, and it looks like I got the ‘8’ inverted. These punches are pretty small, so perhaps I’ll see if there are any orientation marks on their shank to avoid this in the future.

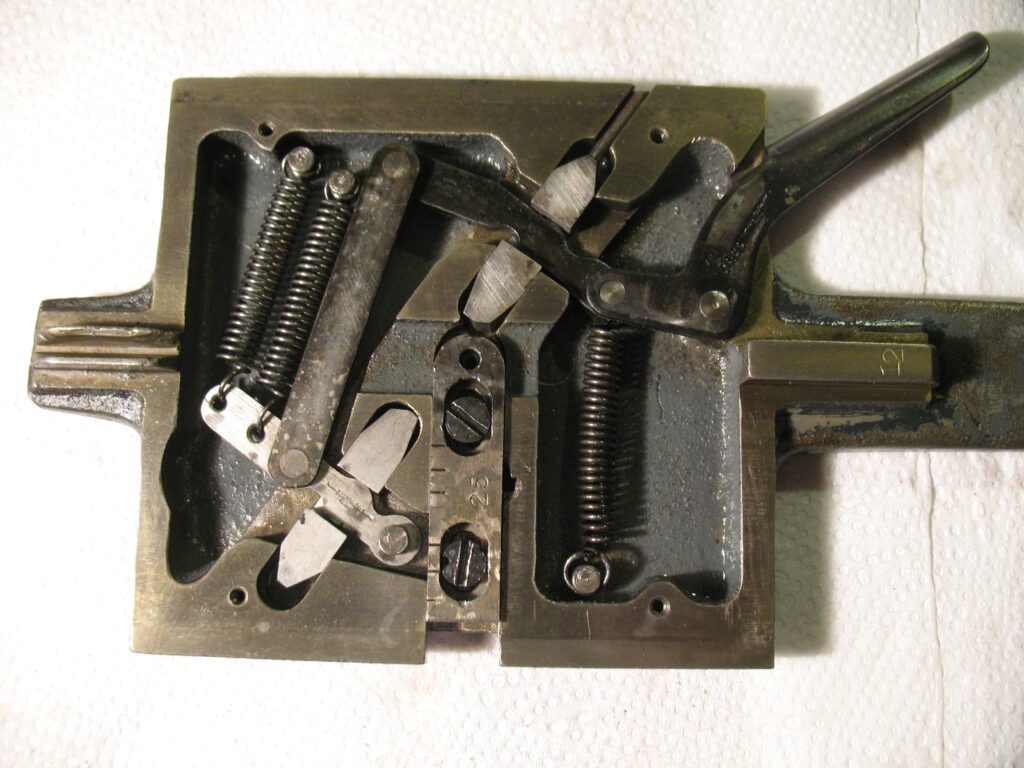

49A Matrix Holder Parts Breakdown

The Monotype 49A matrix holder is listed with plate 35 in the English Spare Parts List book, and although a list of all its parts is included, the holder is not shown in the illustration. This post shows the internals of this holder and identifies all the individual parts.

Note that the adjustment for the mould size has a sort of vernier scale, where you match lines to get the desired position. This allows the individual labels to be far enough apart to be legible. The ‘D’ and ‘E’ suffixes on the sizes would appear to refer to Didot and English point systems. I’m not sure what the ‘A’ refers to, perhaps it refers to an American (Lanston) display mould, which uses the same matrix position in all cases and is the same as the English 36-point position.

The parts are identified by part code, but if they were marked with a part number as well this is shown in parentheses. I’m not actually sure where that spring labeled only ‘?’ came from, as there are no points to anchor either end of it to. Perhaps it was just sitting loose inside this assembly when I first opened it up.

Improved Shim for my 49A Display Matrix Holder

When I cast display type from Lanston display matrices I use an English mould because the one I have is in generally better condition than the American-made Lanston display moulds I have.

This mould’s cavity is not in the same position (except for 12- and 36-point casting) as that of the Lanston moulds, so English Monotype has a special matrix holder, designated number 49A, for this purpose. The holder has an adjustable slide on its back, which one sets to the position appropriate for the body size of the type to offset the matrix position by the correct amount. Each time this is adjusted one also has to adjust the front draw rod on the caster so that that cone hole on the matrix holder gets rough-positioned under the centering pin.

In addition to the difference in mould cavity position, there is also a difference in the height of the face of the mould above the caster table, or perhaps this matrix holder holds the matrix a bit high. In either case, if you have the carrying frame on your caster adjusted for using Lanston matrices, moulds, matrix holders, and matrix diecases, and you try casting with an English display mould and the 49A holder, the matrix does not seat tightly to the top of the mould and the top of the body of each type is surrounded with a daisy/lion’s mane/starburst shaped squirt. If you try to continue running the caster eventually some of this gets left behind adhered to the face of the mould resulting in a much larger squirt.

To correct this, the generally accepted procedure is to place a shim behind the matrix in the holder. Up until recently I have been using two pieces of brass shim stock, one 0.010″ thick and the other 0.012″ thick, for a total of 0.022″ (0.56mm) , which seems to be enough to produce a good seal with the face of the mould. I have, however, found this to be a bit of a nuisance, as seemingly each time I change the matrix one of the shims shift out of position or sticks to the matrix. I have to store the holder with a matrix in place to prevent the shims from falling out and being lost. I have also occasionally found a matrix that needs a slightly thicker shim.

I now have an improved shim. This one is a single piece of 0.015″ shim stock, with 4 layers of adhesive-back aluminum tape for a total thickness of 0.023″ (0.58mm). I have also cut it to a shape that more accurately fits the matrix recess and also is held in, even with the holder empty, by the lugs that retain the matrix. It remains to be seen how durable this is. Oil might gradually loosen the adhesive, and the aluminum itself might wear off.

It remains to be seen how durable this is. Oil might gradually loosen the adhesive, and the aluminum itself might wear off.

One other thing to note is that there is a limit to how thick this shim can be. Clearly if it is too thick the lugs will not be able to engage the beveled corners of the matrix, but even before that point is reached, the lugs will be held open a bit extra by the raised matrix. This will cause the Slide Retaining Pin (part code a49A4) to project from the side of the matrix holder, preventing its insertion into the carrying frame. I’m not certain what the intent of this pin is. It may be to prevent insertion of the matrix holder into the carrying frame if the matrix is not seated properly, or it might be to prevent the lugs from opening when the holder is installed (dropping the matrix onto the face of the mould) if you accidentally press the release lever.

Of course, if you are running your caster adjusted for all English moulds and matrices, the carrying frame on the bridge will be set about 0.020-0.025″ lower and this holder with work fine without any shims.

I have several of these holders so I might consider a third alternative: I could mill about 0.025″ off the rails on either edge which run in slots in the carrying frame. This would allow the holder to sit that much lower, so no shims would be necessary.

Some day I’ll spend some time measuring the vertical dimensions of all my moulds and also of the various matrix diecase types and display matrix holders, to see if I can pinpoint the origin of this height discrepancy. It would also be interesting to determine if the display holders have any vertical play to ensure that the matrix is only pressed to the face on the mould when the centering pin reaches the bottom of its stroke. Although the display matrices are not moving all over the place like composition ones, the mould blade is still opening to the set-width around the time the matrix is seating. It may be that sizing is complete before the carrying frame finishes its descent so this would be a non-issue.

More on that ‘st’ (de câlisse) matrix

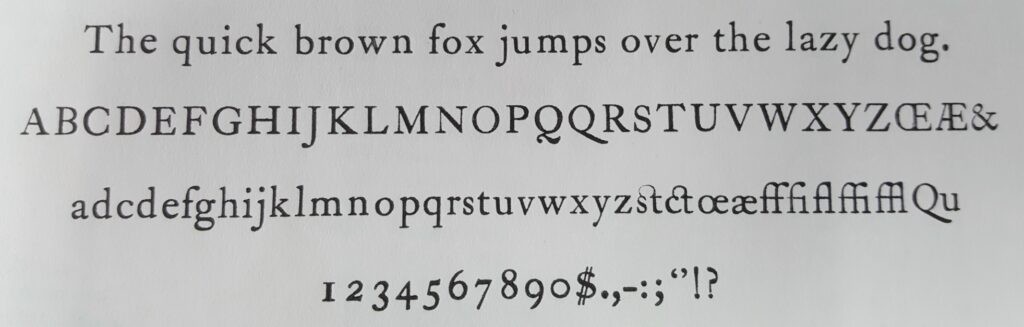

My previous casting of 18-point Caslon Old Style had enough defects that I ended up re-casting it. A couple of the problems are described herein.

After calculating all the adjustments to cast the ‘st’ ligature from the non-factory-made matrix, I was still unsatisfied with the results:

Even though I had its width and alignment corrected, the ‘st’ ligature still seemed to be printing soft at the top.

Standing the type on its face showed that this sort did indeed have a slanted face: The measurement in the image are just in pixels, but knowing how deep the type was (18 points), how tall the type was (0.918″), and about how high the actual face of the type is (top of ascender to baseline, more or less the line standard 0.1591″) I can use proportional triangles to calculate that the top of the printing face is about 0.0065″ (about 0.17mm) low.

Unfortunately, correcting this is not something that can be done with caster adjustments. The mat would have to have its face and back planed to correct the angle, then built up again to get the correct depth of drive and overall thickness.

It turned out I had a much simpler way of fixing this: I had another set of matrices for quaints for 18-point Caslon O.S. which contained a factory-produced electrotype matrix in good condition (and with the correct markings). As a side note this verifies that my set-width estimate was correct.

I had another set of matrices for quaints for 18-point Caslon O.S. which contained a factory-produced electrotype matrix in good condition (and with the correct markings). As a side note this verifies that my set-width estimate was correct.

I also ran into other flaws in the matrices for this font. At first, I thought it strange that the zero (these matrices have hanging figures) was not marked with the same width as the other figures, but a bit narrower. It also cast with a tiny overhang.

Later I noticed that the lowercase ‘o’ was casting too wide, and its matrix has a scuffed-out ‘F’ marking implying that it was a figure. Eventually I figured out that at the factory, the masters for the zero and ‘o’ had been swapped when making the matrices. The matrix with the zero had all the markings, including narrower set-width, of the ‘o’, and the matrix with the ‘o’ had all the markings for the zero, including the ‘F’ designation and a set-width to match the other figures.

Zero on the left, marked as the letter ‘o’, and the letter ‘o’ on the right, marked as the figure zero.

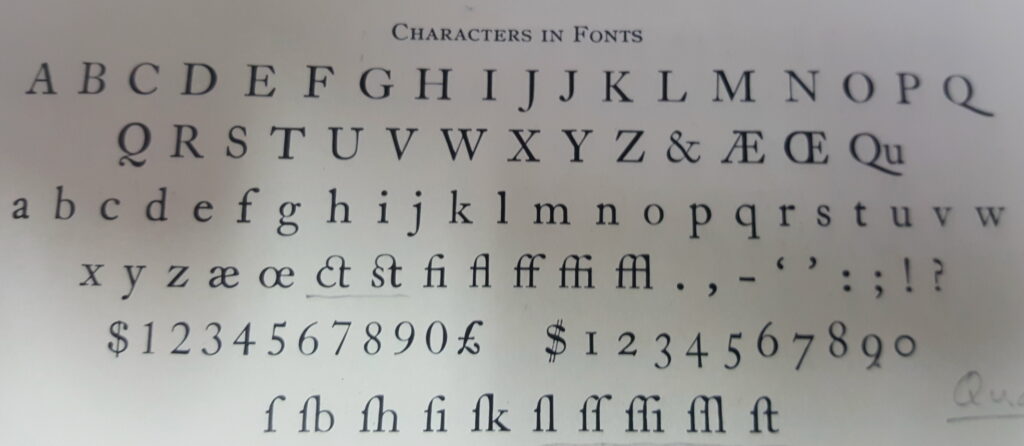

Just to be sure I’m not the one mixing them up, here is the sample from the specimen book: Comparing to both the matrices and my sample at the top of this post, it is clear that I don’t have them confused. The zero is an almost perfect circle of constant stroke width, while the ‘o’ is slightly off-round and has obviously varied stroke width.

Comparing to both the matrices and my sample at the top of this post, it is clear that I don’t have them confused. The zero is an almost perfect circle of constant stroke width, while the ‘o’ is slightly off-round and has obviously varied stroke width.

A third issue which did not result in bad type but was a bit of a nuisance, was that the lowercase ‘p’ seemed to need an extra shim behind the matrix to make it seat properly on the face of the mould. Without this the top edge of the body of the type was surrounded with a sort of lion’s mane of squirt. What baffles me is that I measured the thickness of this matrix and it seems to be the same as many of the other matrices that cast just fine. I also checked for burrs on the face of the matrix and found none. The only thing left to check for (which I have not done yet) is a burr on a back corner of the matrix which could cause it to tilt instead of seating properly. My temporary shim only covered the centre of the matrix, directly over the mould cavity, so that could have seated the matrix flat.

p.s. You would need some knowledge of French-Canadian swearing to understand the title.

Exploding Mould Blade Operating Rods!

During my recent casting run of 18-point Caslon Old Style I found that there were enough problems with the font that I decided to just recast it entirely. I had solved all my alignment, set-width, and substandard matrix problems, so I thought this would be smooth sailing.

Partway through the casting, just as I shut off the pump after casting the last of a particular sort, I heard a loud clang and saw something move out of the corner of my eye. It sounded like some sheet-metal cover had fallen off near the back of the caster.

I released the clutch to idle the caster, and looked around the back of the machine. It turns out the nuts had come off the end of the mould blade operating rod, and the released force of the spring had tried to shoot all the parts across the room. They were foiled in this endeavour by an adjacent metal shelf and its soft contents (plastic bags of soda ash). The clang I heard was the parts hitting the edge of the shelf.

I spent a few minutes finding all the parts, worried that I might have to interrupt the casting job to make a replacement for an irretrievable part. One nut was on the floor directly under the end of the rod. This was probably the locknut which would have just fallen off without much flourish. The spring and inner spring seat were nearby on the floor, coated in cat hair. The rest of the parts were on the shelf, nestled among the bags of soda ash.

I put the outer spring seat and nuts back on the rod, tightening the locknut extra tight (this has happened once before), and proceeded to finish the casting run. If it had not been for the soda ash, some of the parts might have careened into some black hole on the edge of the universe, never to be seen again.

Last time this happened I don’t think I had two wrenches to fit the two nuts and used an adjustable wrench on one of them, perhaps meaning they did not get as tight as they should have. This time I had two wrenches so I’m hoping they are tight enough to stay put.

Other than occasionally verifying these nuts are tight, I’m not sure what to do if they won’t stay on. I’m reluctant to use thread locker, as the pair of locked nuts should already be enough. One thought I had is that compressing the spring puts a bit of torque on the outer spring seat and so tries to unscrew the nuts a bit on each cycle of the caster. If the spring were wound in the other direction it would instead try to tighten the nuts.

Maybe there should be a castellated nut and cotter pin, but the rod is only ¼″ diameter so any such pin would have to be almost microscopic.