We have updated our page describing the new type we offer to include some details on characteristics and typical pricing.

Out of stock: Sisal fibre

It took several years, but our stock of sisal fibre is now sold out. We will be looking for someplace willing to sell it to us in single bale quantities, but for now this product is out of stock.

Please note that we still have sisal pulp in sheet form available.

Grimsby Wayzgoose

The Grimsby Public Library and Art Gallery will be holding their 38th annual Wayzgoose on April 30th, from 9am to 5pm. This gathering of book artists will take place at the Gallery and Library, including the adjacent Carnegie Commons building (the original library), in Grimsby Ontario.

As for the past 18 or so years, the Papertrail will have a table there, selling handmade and marbled paper, bookbinding, papermaking, and marbling supplies, along with new and used books relating to the various book arts.

We will also accept orders in advance for pickup at the fair; please place your orders by Wednesday, April 27th to ensure we can have everything ready. If you want to purchase new type for letterpress, please note that we will charge $5/font for Wayzgoose pickup (there are no shipping charges on other products) and that orders for type will be filled based on available time. We will process orders for type in the order received, so you should order as soon as possible, and no later than April 22nd.

More information including directions to this event are available at their web page.

New type for letterpress now available

We have posted a list of the faces and sizes we have available for casting in our Products section.

An Unusual Monotype Mould

I found an unusual Lanston Monotype 30pt display mould (for the Composition caster and Type and Rule caster) at my last visit to Don Black’s.

What intrigued me was that the top of the blade appeared to be split into two sections. I thought it might be for doing something like casting from composition matrices onto large-body type. Without actually knowing what it was I bought it because such oddball things intrigue me.

Unlike most Lanston display moulds, this one did not have the “scissors,” a pair of levers which transfer spring pressure to either keep the top blade moving with the main blade (for casting type and high quads) or to keep the top blade closed (for casting low quads). There was not even provision in the mould body for the scissors and their pivot. There also appeared to be no other provision for independently controlling a two-part blade.

The mould was stiff with aged lubricant but I managed to pull the blade open. Once I saw the open cavity I realized that what I had was a mould for making cored type, that is, type with a deliberate hollow in the middle to make the formes a bit lighter to handle.

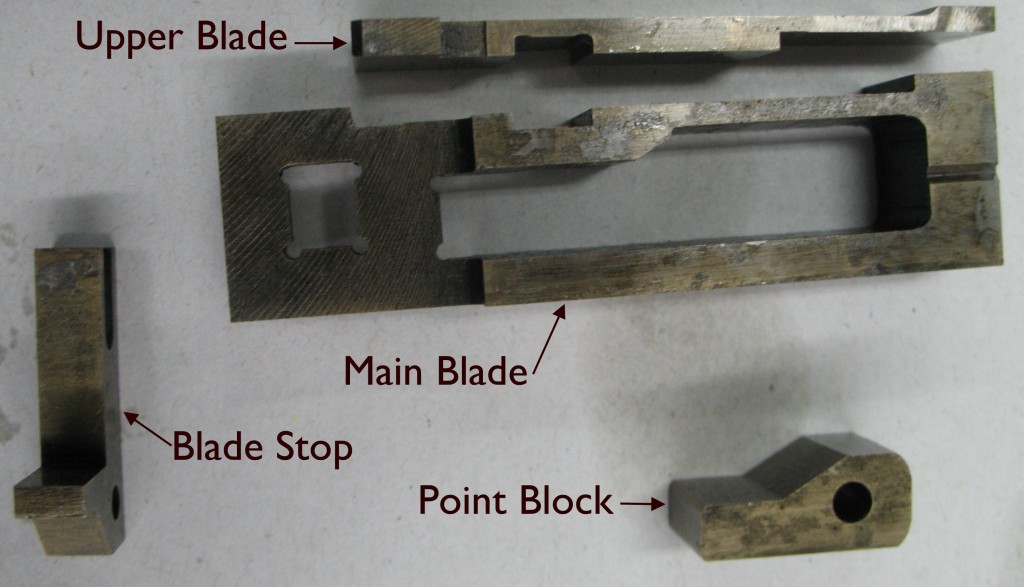

The Lanston Monotype moulds can be refitted with kits for casting various sizes of type, although the kits are custom-fitted to the mould and must match by serial number. This is what the usual blade kit looks like:

Here are the corresponding parts for the cored-type blade:

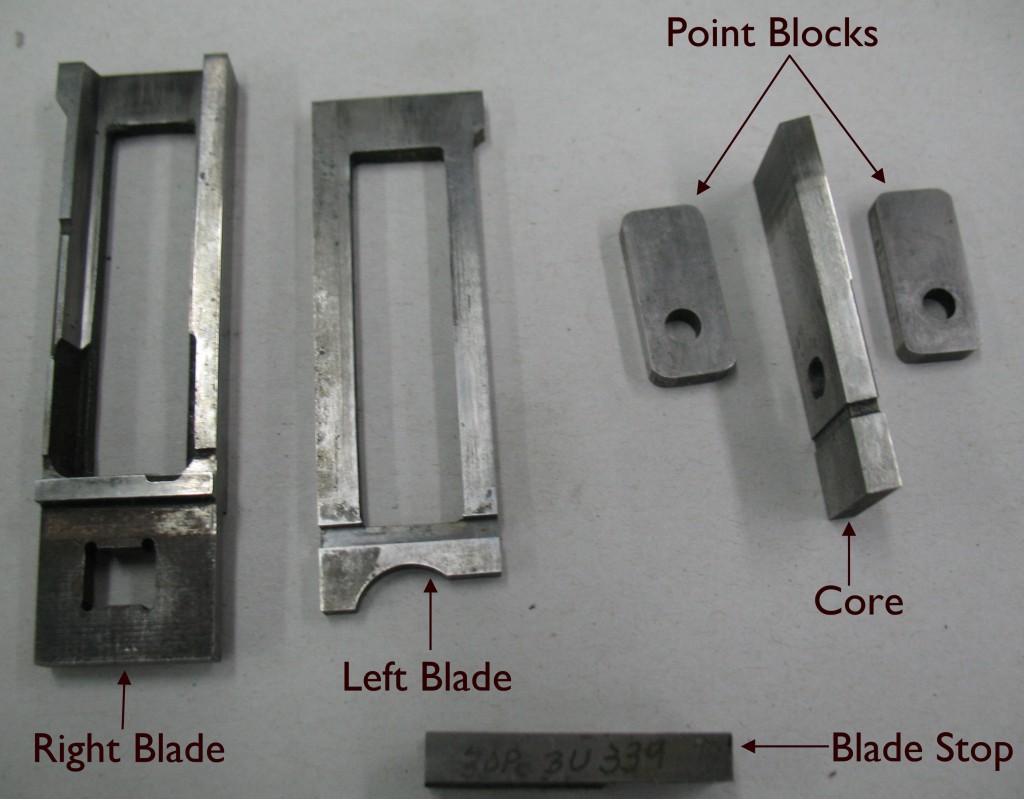

Here are the corresponding parts for the cored-type blade:

A tang near the rear of the right blade engages in the left blade so the two always move in unison. The core nestles into the recess in the right blade. The blade stop is a simple rectangle (rather than the duck-head shape of normal blade stops) because it does not have to provide a stop for any upper blade. The thickness of the core plus the two point blocks determine the point size of the type.

A tang near the rear of the right blade engages in the left blade so the two always move in unison. The core nestles into the recess in the right blade. The blade stop is a simple rectangle (rather than the duck-head shape of normal blade stops) because it does not have to provide a stop for any upper blade. The thickness of the core plus the two point blocks determine the point size of the type.

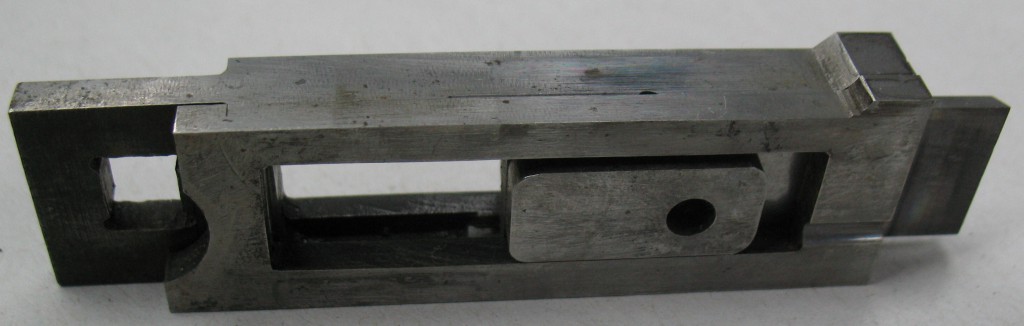

This shows the assembled blade and core:

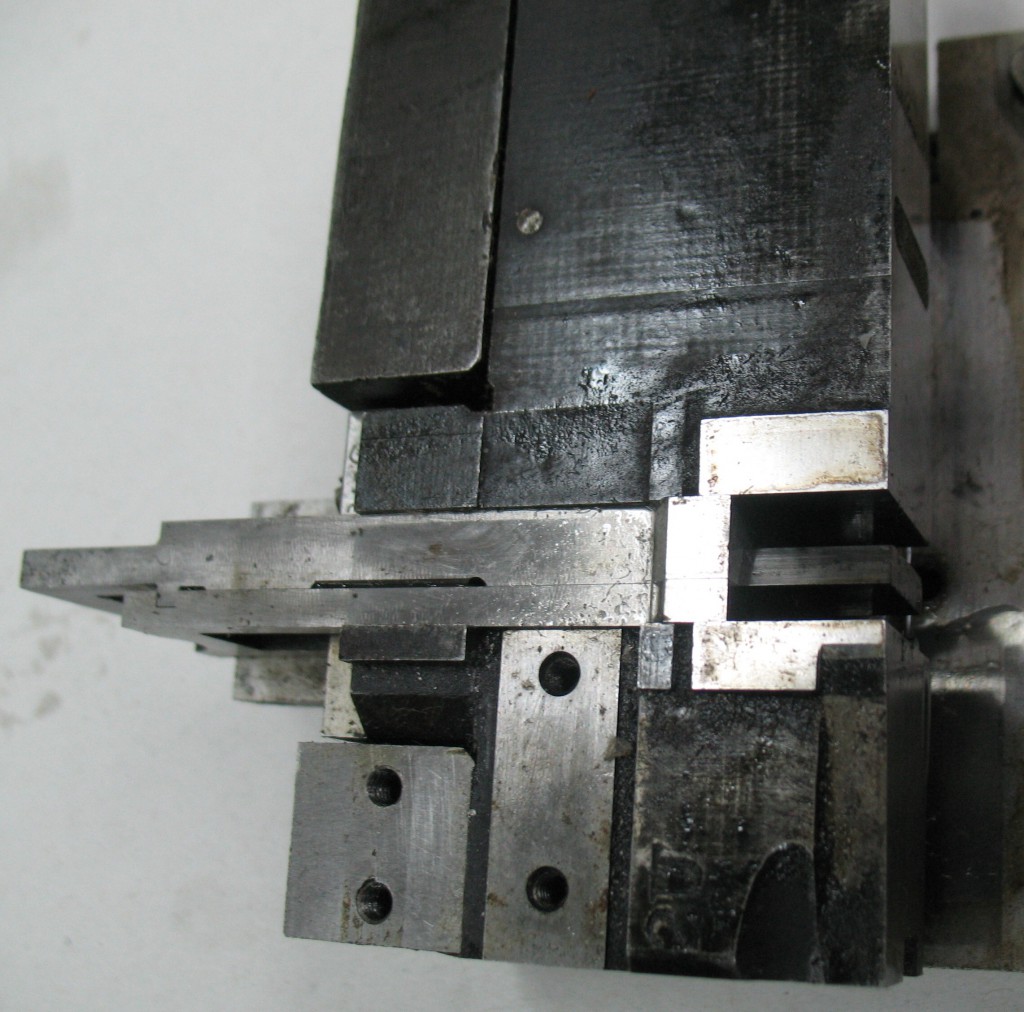

Finally, when the blade in installed in the mould and retracted (with crossblock removed as well), this is what you see:

Finally, when the blade in installed in the mould and retracted (with crossblock removed as well), this is what you see: The end of the core come just a little short of the ends of the left and right type blocks, so the cavity in the type would probably not quite go all the way through. The slot between the two halves of the blade allow oil to lubricate the contact between the core and the blade halves. This particular mould does not appear to be that heavily used, but based on the condition of the screw heads it does look like it was disassembled often so during its service life it may have been a bit of a troublemaker!

The end of the core come just a little short of the ends of the left and right type blocks, so the cavity in the type would probably not quite go all the way through. The slot between the two halves of the blade allow oil to lubricate the contact between the core and the blade halves. This particular mould does not appear to be that heavily used, but based on the condition of the screw heads it does look like it was disassembled often so during its service life it may have been a bit of a troublemaker!

New Dryer Felt

We have been unable to obtain any more of the dryer felt we used to sell for use in paper drying stacks.

We have a replacement material which is also spin-bonded polyester, but it has only about half the weight per unit area compared to our old felt. On the other hand it has a much higher loft: its uncompressed thickness is about 2cm (¾″).

If you clamp your drying stack tight enough this will flatten out like the old felt did, but by leaving the clamps or straps a bit looser, this felt will remain open, thus allowing more air circulation closer to the paper. The higher loft also means that the ridge pattern on the corrugated dryer boards will be less likely to transfer to the dried paper.

One downside is that the higher loft makes for bulkier parcels and higher shipping costs on orders.

Finally, the new felt is 90″ (229cm) wide, giving a little more versatility for cutting to size than the old 60″-wide felt. We sell it in cut lengths at $4.90 per linear metre.

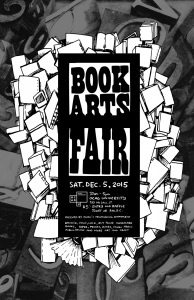

The 2015 OCADU Book Arts Fair, December 5th

As in previous years, the Papertrail will be participating in the annual Book Arts Fair held in the Great Hall of OCAD University, 100 McCaul street in Toronto. This year’s fair will be on December 5th, running from 10am to 5pm and will feature many artists and craftspeople selling their prints, handmade paper, books, small press publications, and more.

As in previous years, the Papertrail will be participating in the annual Book Arts Fair held in the Great Hall of OCAD University, 100 McCaul street in Toronto. This year’s fair will be on December 5th, running from 10am to 5pm and will feature many artists and craftspeople selling their prints, handmade paper, books, small press publications, and more.

We will be selling our marbled and handmade papers, along with a selection of bookbinding, marbling, and papermaking supplies and new and used books related to the book arts.

Hope to see you all there!

Some Pix from Gaspereau

So here it is three weeks later and I’m finally posting some of my photos from my visit to the Gaspereau Press Wayzgoose.

With Hallowe’en coming up many of the yards in Kentville were decorated with Pumpkin People. These are the ones in the yard of the B&B where I stayed:

Having driven all that way (mostly in the rain) it would have been a shame not to do at least a bit of touristing. Friday was sunny but a bit cool and windy, so I spent the morning in Halifax, where I visited the Citadel, taking a guided tour included a loud and smoky firearms demonstration. For both this and the noon gun firing the guide pointed out that the best time to click the camera shutter was also as the best time to cover your ears, leaving one short two hands! I opted to take the photo and tolerate the noise; strangely I found the noon gun (a cannon with a 2-pound charge of black powder) to be less noisy than the rifle, probably because there was no stone wall to reflect the sound right back to me.

Having driven all that way (mostly in the rain) it would have been a shame not to do at least a bit of touristing. Friday was sunny but a bit cool and windy, so I spent the morning in Halifax, where I visited the Citadel, taking a guided tour included a loud and smoky firearms demonstration. For both this and the noon gun firing the guide pointed out that the best time to click the camera shutter was also as the best time to cover your ears, leaving one short two hands! I opted to take the photo and tolerate the noise; strangely I found the noon gun (a cannon with a 2-pound charge of black powder) to be less noisy than the rifle, probably because there was no stone wall to reflect the sound right back to me.

I hit the shutter a bit late so he had already lowered the rifle from his shoulder, but there was still plenty of smoke from the black powder.

It is a shame that all the high-rise development in downtown Halifax is slowly blocking off the amazing view of the harbour entrance that made the Citadel and its associated fortifications so impregnable.

After the Citadel I stopped for lunch at one of Audrey’s old hangouts from her days as a Lexx groupie attending their “uncon(vention)s.”

No shoes for sale, just good food and drink. Apparently the place got its name from the sign they found collecting dust in some storage room.

Friday afternoon was spent at Gaspereau helping a bit with the setup, poking around in the dark corners, and generally avoiding being in the way of the real work. I had a quick look at their mothballed Monotype caster (an American Composition Caster not fully equipped for display casting) and scored a partial can of genuine Monotype Mould oil. There were several partial cans there and I told Gary Dunfield that if he repackaged it into, say, 1L (about 1 quart) cans her could probably sell it on eBay or at an ATF conference.

Saturday was busy enough that I ended up missing the talks and spent the day in the letterpress shop. For a while I was helping George Walker diagnose a skipping gear on the form rollers of the Vandercook he was using. Ultimately the problem seemed to be caused by the very tacky ink he was using. I didn’t really get a chance for photos until it was cleanup time, so you don’t see the crowds in the photo, but at least you get to see some of the featured guests.

In the foreground (wearing the hat) we have George Walker speaking with Monica Kidd. Behind them all, at the far end of the room, Nick Kennedy and Christine from Trip/Print Press in Toronto are finishing their cleanup. I unfortunately can’t recall the names of anyone else in the photo; some of them are of course the last of the visitors, but there are at least two other featured guests at least partly visible.

There is also an excellent video taken by some unnamed member of Nova Scotia Printmakers which includes some of the cleanup and a wonderful recitation of Jabberwocky by George Walker.

Going to the Gaspereau Wayzgoose

I’ve decided that this year, I’ll finally spend a few days to attend the Wayzgoose at Gaspereau Press in Kentville, Nova Scotia. This year the event takes place October 24th, and I plan to drive there and back, a 2-day trip each way.

If you’re somewhere along the Toronto-Montreal corridor, want to visit this wayzgoose, and want to save a bit on travel costs, I’d be willing to give you a lift. We could share gas and perhaps hotel costs, and we’d both have someone to talk to! I would be leaving New Dundee early Wednesday morning (the 21st) so I can spend Friday hanging out in the Kentville area, and probably returning late Monday night (the 26th), but these times are pretty flexible.

Also, if you know of any letterpress shops worthy of a visit along the route, drop me a note because I could certainly use a little diversion for the long drive!

Finally fixing an arduino shield

Three years ago I attended SoOnCon 2012 hosted by Diyode in Guelph. The “badge” for this event was an Arduino Uno board, with Codeshield, a shield of general-purpose sensors and actuators, all mounted with a battery pack on a custom-made plastic base that acted as the badge per se:

The battery pack is held by Velcro strips, and the Arduino and shield are held because their connecting pins go through matching holes in the badge.

The battery pack is held by Velcro strips, and the Arduino and shield are held because their connecting pins go through matching holes in the badge.

This was provided to the conference registrants as a kit, with the shield board needing full assembly. In the process of assembling mine, I damaged the internal wiring of the servo. I had cut the cable short for a tidy installation, and while stripping the ends of the wires I ripped the connection off the internal board (there is no strain relief on the cable). I opened up the servo and tried to solder the wire back on. Adding to the confusion at the time were some annotations that there was an error in the assembly instructions regarding the connections of the servo.

Once I had the whole thing assembled, everything seemed to work except the servo. I attributed this to the assembly instructions lack of clarity regarding their own error.

I don’t particularly have a use for this, so it has been collecting dust near my desk since then. However, last week I found out that a group from Diyode had visited my daughter’s class to teach them about programming, and they were using this very same shield and Arduino. I figured that I should get the servo working properly so Lily could fool around with it at home.

After re-examining what was still available of the assembly instructions online, looking up the servo specifications, and measuring some voltages on the board, I determined that the servo itself was defective. Obviously, my “repair” did not work. I bought a compatible replacement and wired it in (this time leaving plenty of cable length), and behold! The servo now works!

There is still one oddity, though. The default demo code uses the thermistor to control the LED colour; as you warm up the sensor, the LED should fade from green to red, but instead, the red gradually brightens and the green suddenly goes from full-on to full-off. The Arduino supports PWM control on some of its output pins, and for some reason the runtime library seems to think that my particular model of Arduino does not have PWM support on the pin that drives the green LED. Perhaps the code loaded onto the card was built using the wrong model of processor, one which does not support PWM on this pin, so it reverts to simple on/off.

I still have the IDE on my computer, but I have to hunt down an A/B USB cable so I can reprogram the board.