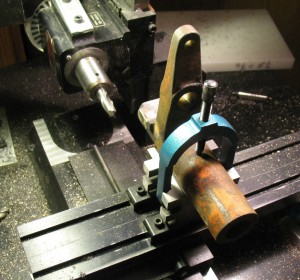

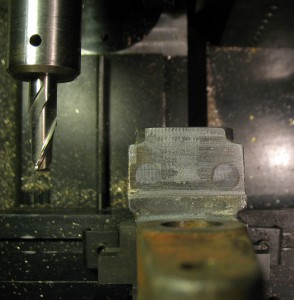

In order to repair two threaded holes in the Monotype caster pump latch, I thought I would have to make an extension for my drill bit because the holes to be drilled were so close to a side arm on the part. However, it turned out that I could place the required drill bit (#29 if I recall) in the collet chuck of the flex shaft handpiece of my Dremel. It is a bit of a cheat since #29 is larger that the 1/8″ size the collet is made for but I managed to get the bit held properly anyway. It is also slow work because the Dremel motor easily gets bogged down. Essentially I have to turn it on to a speed that is far too high for a drill bit of that size, then apply enough drilling pressure by hand to slow the motor down to the right speed but not stall it completely. On the other hand the long handpiece makes it easy to visually keep the hole sufficiently square to the surface.

I will not be threading the holes to their original specifications, which is 5/32-36 with what I believe to be a 55° thread angle as I am willing to neither make nor purchase a custom-sized tap for the purpose. Instead I will be using a modern #8-36 tap, whose major diameter 0.164″ is slightly greater than 5/32 (0.156″) and whose thread angle is 60°. The original screws will screw into the new holes, but will have a weakened hold, so I may use #8-36 screws as well, with their heads modified to match the countersink depth.

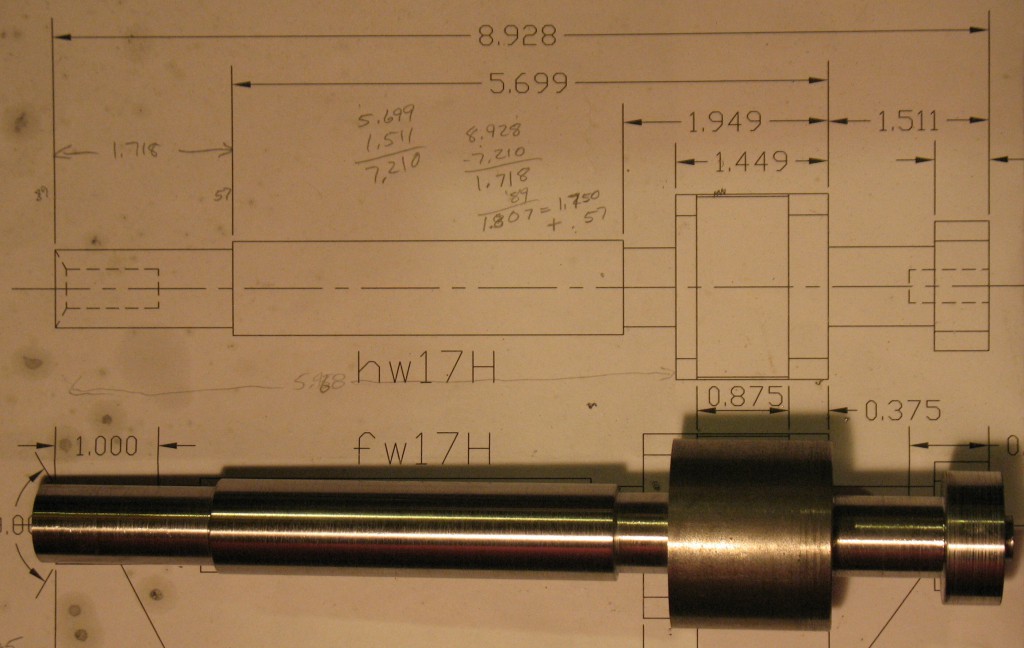

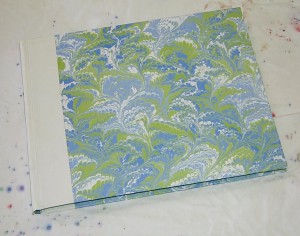

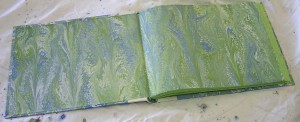

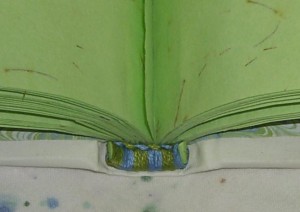

Anyway, here are a couple of pictures of the drilling process: