When I was younger I did a lot of the service myself on my old Valiant. This car was made when the early rounds of pollution controls were added so the engine was still relatively simple to service. After that, though, vehicles became more complex to service, and I had better things to do with my time so I migrated over to having a repair shop do most of the work. Finding a shop that I liked and trusted helped a lot too.

Lately, however, I’ve been finding that repairs are getting pretty expensive. Both my car and my truck are over ten years old, so they are getting to that stage where repairs can get a little more involved.

A few months ago the rear brakes on our car started to make a horrible scraping/screeching noise when applied. I had also been getting the ABS warning light showing occasionally. A quick inspection confirmed that new rear brake pads were required. I had already spent quite a bit on some other vehicle repairs, so I decided to replace the pads myself. For the benefit of anyone searching the internet for car repair tips, our car is a 2001 VW Golf GLS with 2L gasoline engine, produced for the Canadian market. I know of at least one part, the exhaust flex pipe, which seems to require the aftermarket part designated for 2002 models rather than that for 2001s.

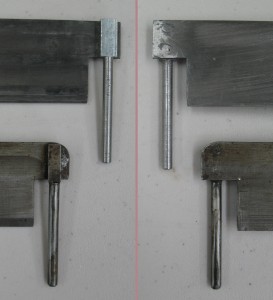

I had no trouble removing the calipers to get at the pads, but this is the first time I had serviced rear disk brakes, which include the parking brake mechanism. In order to make room for the new thick pads, the pistons had to be retracted back into the caliper, but the parking brake mechanism meant that the they could not just be pushed straight back in. A special tool is required which not only pushes on the piston but also turns it, essentially screwing it back onto the parking brake actuator system. Fortunately these tools are readily available and soon I had everything reassembled with the brakes working nice and quiet again.

Over the ensuing months, the brakes developed a substantial pulsation. This was not a smooth pulsation, but a quite abrupt clunking as the wheel rotated (with accompanying pulsations felt at the pedal). We would be leaving on a long car trip soon, so I had to have another look at the brakes.

By jacking up first one rear wheel then the other, and gently applying the parking brake, I identified which side had the problem. It was the same side that had the metal-on-metal contact from a completely worn pad before I replaced the pads. I removed the wheel and the caliper, and this time I also removed the brake disk. The rear face of the disk had apparently developed a scale of corrosion before the pads were replaced, and now most of the scale had come off, leaving two patches of scale making the disk thicker in those places. The scale was perhaps half a millimetre thick. I chipped off the rest of the scale using the crude approach of banging on it with the head of the lug wrench. The rest of the scale came off pretty easily. I also use compressed air to blow out dust and metal filings from the ABS wheel speed sensor. With everything reassembled, we now get nice smooth stops again.

I was hoping that cleaning the speed sensor would get rid of the ABS warning light but it has not. I think I’ll have to fork out some money to get the local VW dealer to read the diagnostic codes from the ABS controller so I have a better idea what it is complaining about. One other thing I noticed while doing this second repair is that the rubber dust boot on the piston was torn, probably damaged during the piston retraction of the first repair. I suspect that before retracting the pistons I should have loosened and lubricated the groove where the boot engages in the piston so the boot would not twist along with the piston. I guess I should fix these before winter, but that work is more involved because the piston must be removed, which then entails bleeding the air out of the hydraulic system.