We just came home from an overnight trip to Niagara Falls. The Falls and river gorge are breathtaking sights in themselves, but you eventually tire of them and start looking for other activities. This weekend was also particularly hot, and there was a lot of walking, so the things we often found ourselves seeking were shade, air conditioning, and a place to sit.

In this vein the first thing I would recommend is getting a day pass for the WeGo bus ($9 for an adult good for 24 hours from first use). In addition to saving on a lot of walking this fulfills both the air conditioning and (usually) place-to-sit requirements. Just don’t wait too long to purchase your passes: we found that after 5pm the Niagara Parks kiosks closed, making it harder to find a place to purchase the passes. Apparently many of the hotels sell them, but we purchased ours at the Secret Garden Gift Shop just a little off the main drag. Parking is expensive ($10/hour, max $30/day, no in/out privileges at the lots run by Niagara Parks) so once you’re parked you want to make a full day of it. Other than walking and the bus you can also rent bicycles, scooters, and three-wheel vehicles from various places (but then you have to park these somewhere too!).

The main place for tourist attractions is Clifton Hill, a two-block-long road which runs from Victoria Avenue down to the Niagara Parkway, pretty much just opposite the American Falls. This street is very busy, and is packed with restaurants, hotels, and carnival-like attractions. Unfortunately, though not unexpectedly, we found that most of these attractions felt overpriced, if you consider the cost of admission and the amount of time it takes to visit. The restaurants also seemed expensive for just a quick meal; there was a Wendy’s but we had eaten Wendy’s on the trip down the day before.

We ended up finding places away from Clifton Hill to eat: Friday dinner at Phở Ginger in Niagara Falls on Victoria Avenue just half a block from Clifton Hill, Saturday breakfast at a regular Tim Horton’s at the corner of Murray and Stanley streets, Saturday lunch at Big Hungry Moose food court on the Niagara Parkway just on the north edge of town, and a cooling ice cream break at Reg’s Candy Kitchen along the Parkway under the Rainbow Bridge Canada Customs plaza, where Reg has been making fudge and other candies for decades (Reg, still there stirring his kettle of fudge, told us how long but I forget now).

The attractions that we went to (other than the Falls themselves, of course), generally in descending order by enjoyment and perceived value-for-money, were:

- Bird Kingdom, a large indoor aviary (actually several separate aviaries, at least two of them are walk-in ones) with hundred of birds of various species. We all enjoyed this, plenty of birds to see and the large multi-level aviary is really nice. There was also a short section on the history of the building itself, but we rushed through this because we (and more relevantly, people behind us) just wanted to get to the birds!

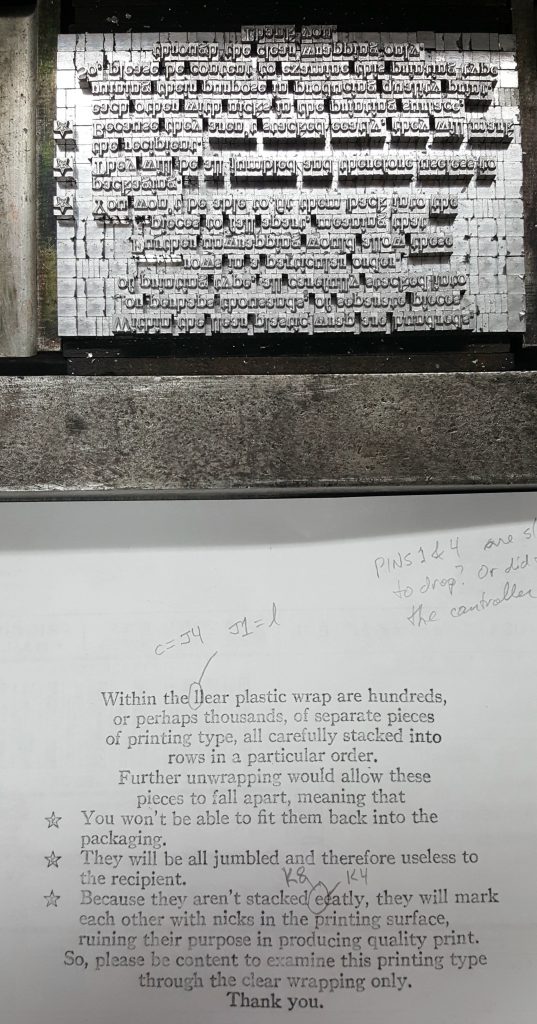

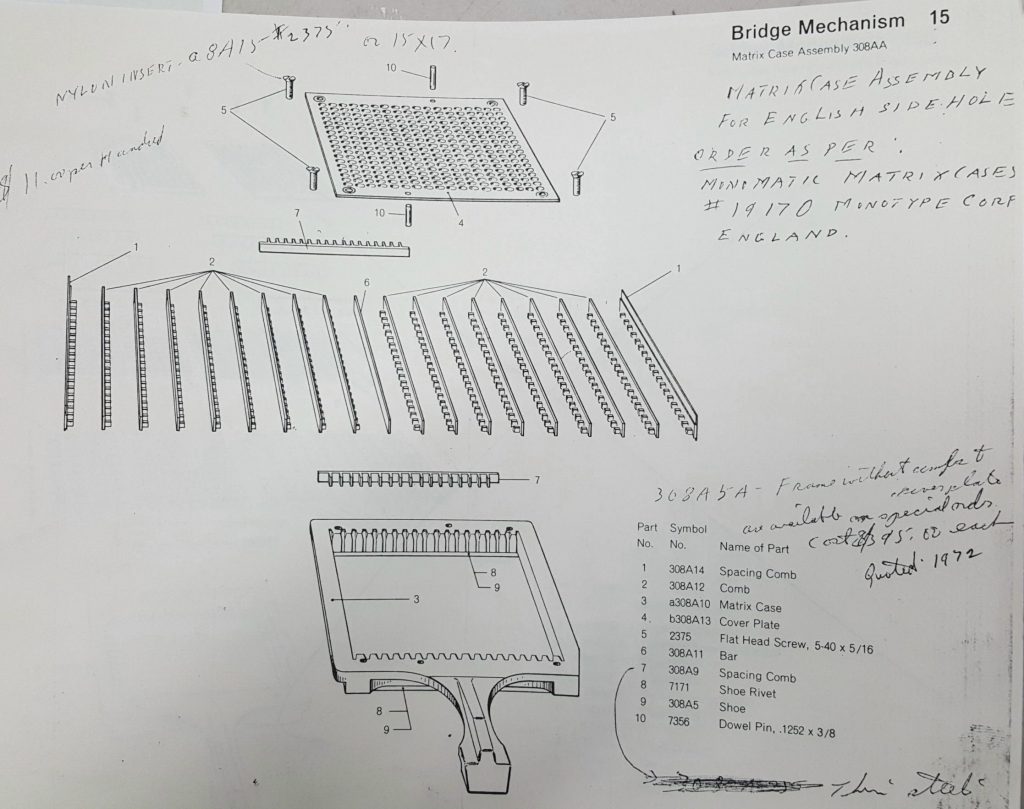

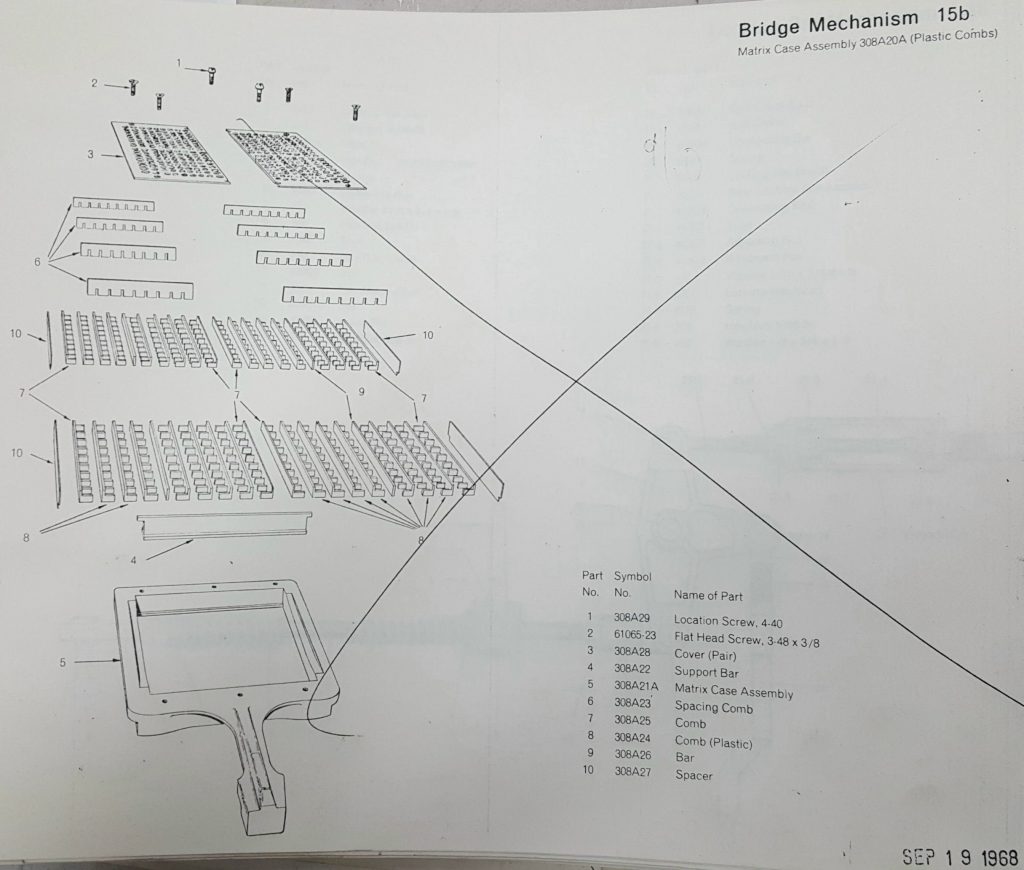

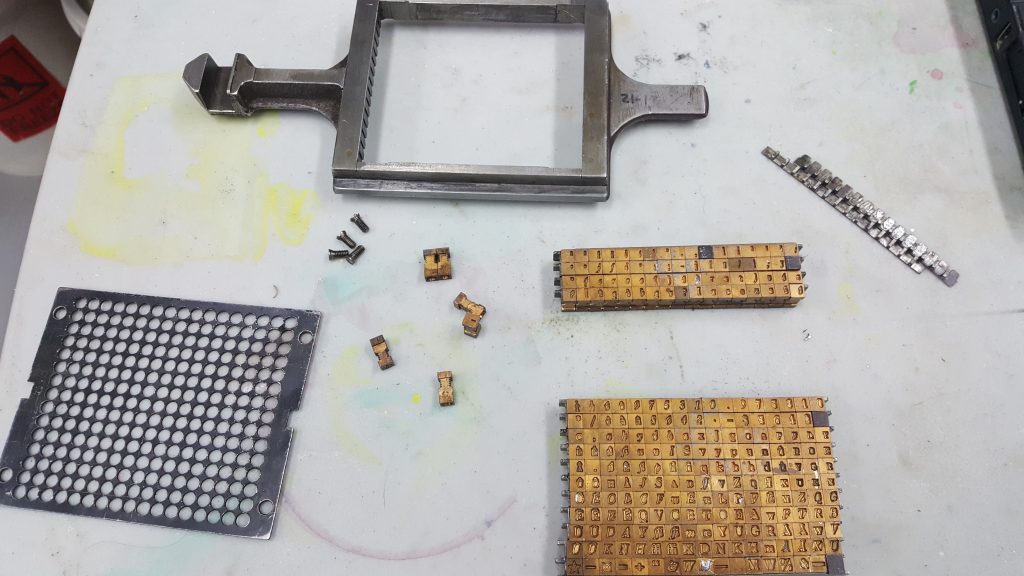

- Ripley’s Believe it or Not! Aud and Lily visited here while I spent the morning at the Mackenzie Printery and Newspaper Museum in nearby Queenston, and they both say it was interesting and worthwhile.

- Niagara Speedway multi-level go-kart track, Lily’s first time driving anything other than a few minutes on our riding mower.

- Louis Tussaud’s Waxworks: though interesting this pales in comparison with Madame Tussaud’s in New York both in size and quality. The figures looked fairly good but I found that some of them needed work in the hair department. For instance, Sean Connery in his James Bond persona has just plain and rather long combed hair rather than the shorter and slicked-over cut that he had in the movies.

- mirror maze at Big Top Amazing Mirror and Laser Maze (not the similar Crystal Caves nor the mirror maze at Niagara Falls Funzone). This actually consists of two hexagon-pattern mirror mazes joined by a square-pattern curtain maze and some other joining features. The mirror mazes were accurately built (insofar as the apparent hallways created by the reflections remained straight off into the distance) and kept very clean (we were given gloves, partly for COVID purposes but also to keep the mirrors clean) but I found them to be disappointingly simple mazes. They would have been more challenging if they had contained some glass (non-mirrored) panels and some looped passages. Without such features you could easily tell you had entered a dead-end because you saw your own reflection in all directions except the one you came from.

There are combination passes for some of these which can save a bit of money, but you really have to know ahead of time what you might want to visit if you buy one of these. If you don’t use all the attractions the pass is good for you’re pretty much better off buying admission to the individual attractions.

One attraction that we did not visit but I think we should have is the Niagara Parks Power Station, one of the many hydro-electric generating stations in area, which no longer generates power but has just this summer been opened as a sort of museum. This plant was built in 1905 as the first major development of electrical generation on the Canadian side of the Niagara River, and still contains all of the now disused machinery. The building itself reflects the grand architectural style of the day and so adds to the interest.

This was one of the first attractions that we looked into, and unfortunately I balked at the admission cost ($20 per person), but now that I’m more familiar with what most of the other attractions cost, that doesn’t seem so expensive.