This post provides a detailed view of one of the mechanisms in the Monotype paper tower. When the Quadding mechanism is engaged a notched wheel on the front side of the paper tower turns one position per cycle, and the (absence of) a notch on this wheel prevents the ribbon from advancing, causing the character coded by the current ribbon position to repeat until the counting wheel advances to the next notch. In this manner a character can be cast 5 or 10 times (depending on how the notched wheel is set) from a single row on the ribbon.

This would save some keyboarding time and make ribbons shorter for material with a lot of wide spacing or leaders in the lines, but otherwise would not speed up the caster. When using a computer interface, this feature is essentially pointless.

It is also a bit of a nuisance because if the counting wheel is not at a notch position but the ribbon is not on a row signalling for quadding, the ribbon will never advance because the counter wheel will not turn. This can happen if the ribbon is manually repositioned during a quadding countdown or if the counting wheel is accidentally moved manually.

Because this is only marginally useful and somewhat of a nuisance, many casters I have seen (including my own) have this feature disabled by removing the arm that senses for a notch in the counting wheel. The ribbon advance then essentially always senses a notch and thus always advances the ribbon.

Despite the limited utility of this mechanism, I had my paper tower disassembled and cleaned so I am posting some photos of how the counting wheel is advanced.

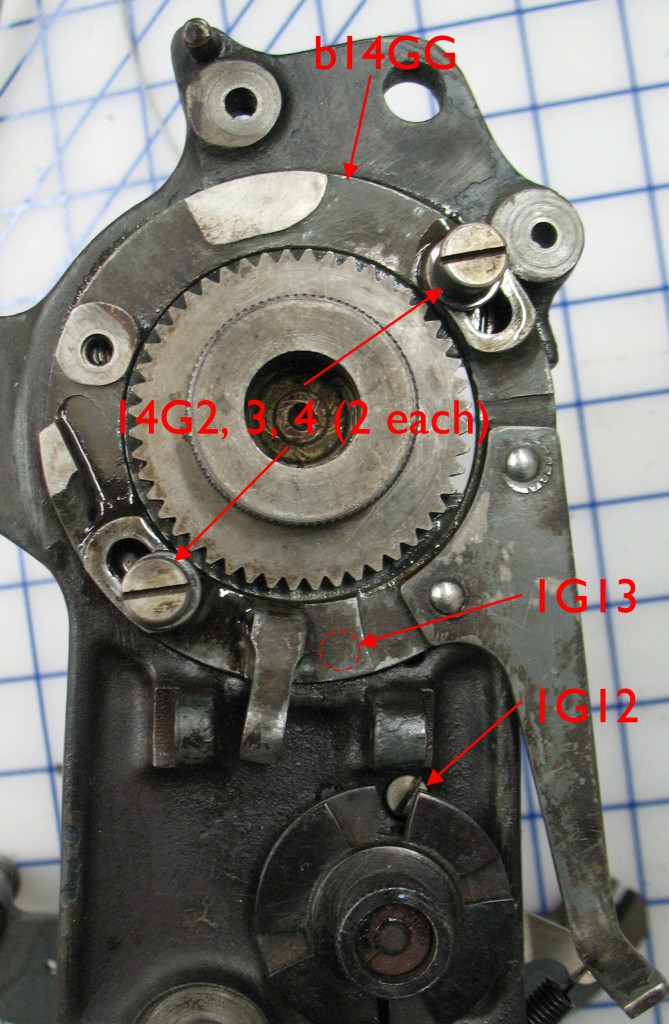

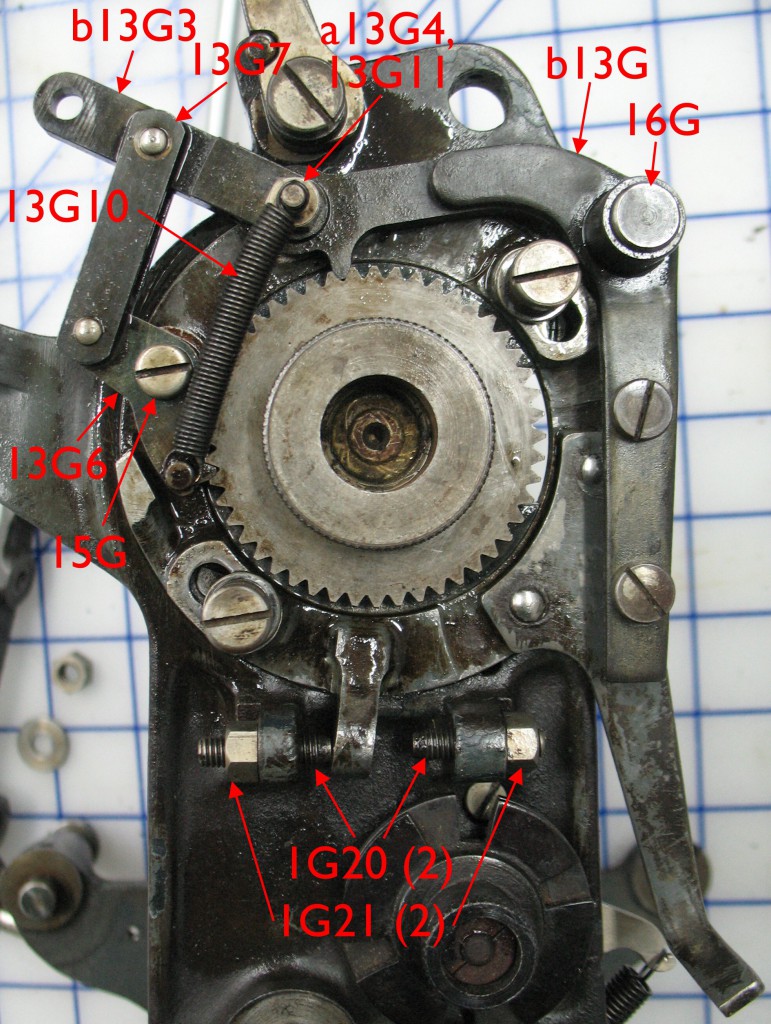

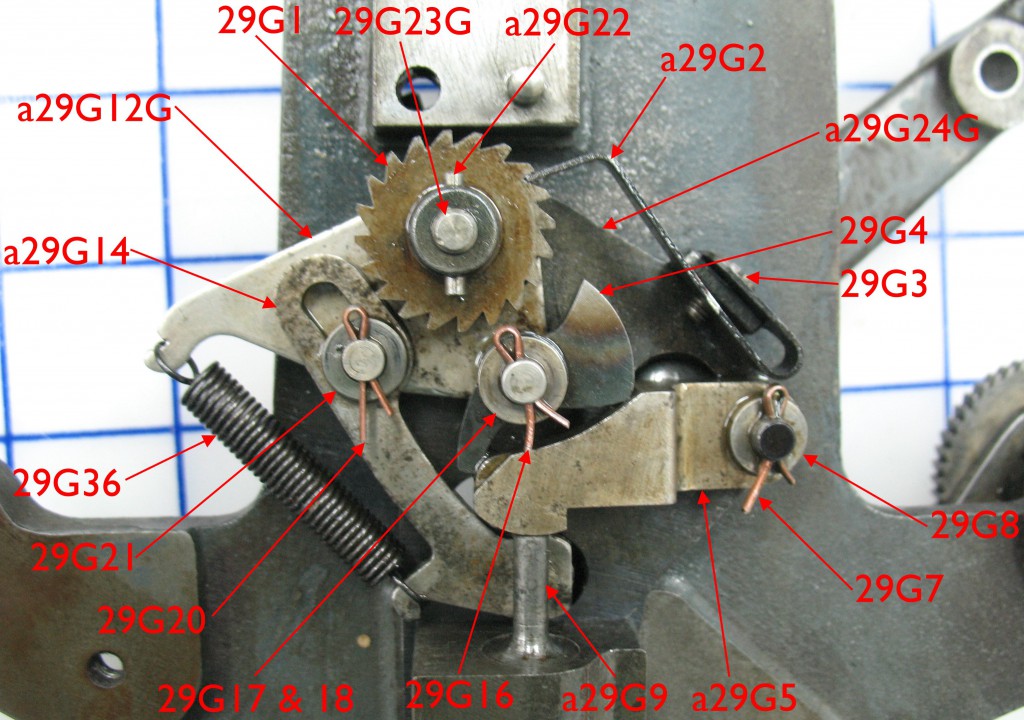

First, the mechanism, with parts identified by symbol:

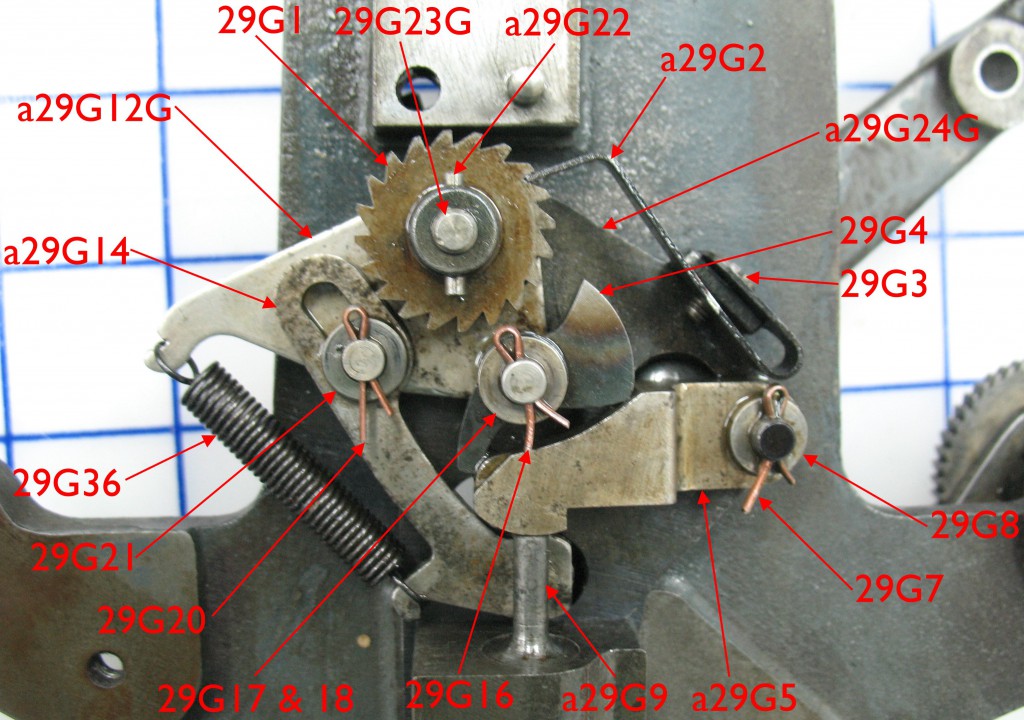

This view is of the inside of the front end plate of the paper tower; in the assembled paper tower this view direction would be obscured by the air pipes and the entire area enclosed by the side covers of the tower. My mechanism is missing 29G17, a spring (wavy) washer behind the plain washer 29G18, but it seems to operate fine without it. The parts are illustrated on Plate 49 of Spare Parts List for Monotype Composition and Type and Rule Casters (Monotype Corporation), and also on pages 62/63 of Plate Book, Monotype Typesetting Machine, the Composition Type-Caster (Lanston Monotype Machine Corp, 1955)

This mechanism is driven by a pin on the air tower lever c19G which passes through the tower side panel and engages link a29G14 about where the arrowhead for a29G9 is. The pin is eccentrically mounted on the air tower lever to provide some adjustment to the quadding counting wheel mechanism.

The ratchet wheel 29G1 is held at one of 20 positions by the detent spring a29G2, and is pinned to the counting wheel shaft assembly 29G23G by the taper pin a29G22.

When Quadding is not selected by the ribbon, the mechanism moves but does not rotate the ratchet wheel:

When the air tower lever is at the top of its stroke, the pawl 29G4 is rotated clockwise by contact with the pawl lever a29G5.

As the air tower lever descends, the pawl moves clockwise around the ratchet wheel.

When the air tower lever has descended all the way the pawl has moved further around the ratchet wheel but remains disengaged from it.

The return stroke is the same sequence in reverse.

If the ribbon row selects quadding, at the bottom of the stroke air is admitted through the ribbon to the various air lines, and the quadding actuator piston a29G9 rises pushing the pawl lever a29G5 up, which in turn rotates the pawl until it engages the ratchet wheel.

The pawl has been engaged in the ratchet wheel by the actuator piston.

As the air tower lever rises the movement of the pawl rotates the ratchet wheel. The air is released from the ribbon air bar and the actuator piston drops again.

With enough rotation the detent spring a29G2 drops into the next ratchet tooth.

The pawl contacts the end of the pawl lever which starts to force the pawl back to its disengaged position.

Once the pawl is disengaged from the ratchet wheel the detent spring snaps the ratchet wheel back a bit and the mechanism is back at its idle position from the first photo.

There are three adjustments in this mechanism: The detent spring can be shifted up or down so that the pawl disengages just after the spring catch drops over a ratchet tooth. The eccentric pin on the drive arm can be rotated to move the entire range of motion of the arm a29G14 up or down so the pawl reliably engages a ratchet wheel tooth without excessive slop and also to a lesser extent to adjust the length of this stroke. Not shown here, but the arm on the ribbon advance mechanism that senses the presence of the notch on the counting wheel can also be adjusted to match the notch position. None of the copies of the book Casting Machine Adjustments I have seen describe these adjustments, probably because they predate the Quadding feature. I do however have an article entitled Automatic Quadding and Centering on the Monotype by Lanston which gives a somewhat rote adjustment method. It essentially amounts to setting the eccentric to a central position, adjusting the detent spring so the pawl engages with 0.020″ clearance from the ratchet tooth, then fiddling with both adjustments aimlessly if it does not advance properly.

Although there are openings in the two paper tower covers to allow oiling of this mechanism it is difficult to oil it properly without just shooting in a big squirt of oil and hoping it hits all the moving parts. Removing the left cover of the paper tower gives better access allowing the oil to be applied to all the moving parts properly.

The geometry was fairly simple, but the dimensions had to be accurate to ensure that the pawl did not have too much play, which would have led to increased wear of the ratchet wheel and misalignment of the ribbon holes over the air ports. It fits well, although I cut the threads a bit deep, possibly weakening the threaded portion of the pin, but I don’t think there is enough pullout force to break it.

The geometry was fairly simple, but the dimensions had to be accurate to ensure that the pawl did not have too much play, which would have led to increased wear of the ratchet wheel and misalignment of the ribbon holes over the air ports. It fits well, although I cut the threads a bit deep, possibly weakening the threaded portion of the pin, but I don’t think there is enough pullout force to break it.