Because it only lasted one day, the participants in our recent Washi workshop were unable to experience the joys of taking the sheets off the post and apply them to drying boards. Over the next couple of days we pressed the two posts and occasionally changed out blotter sheets until they seemed dry enough to handle. My previous uncertainty about how dry the post should be is now somewhat diminished: it seems you want the post on the dry side, to the point where fresh blotters don’t absorb much water any more. If you peel off the felt that is against the sheets and hear a wet “shhhhhh” sound it needs more draining.

One problem I encountered is that I forgot to place a couch on the top of the larger post, so the stack of paper was well attached to one of the press boards. The last sheet did not peel off the press board very cleanly.

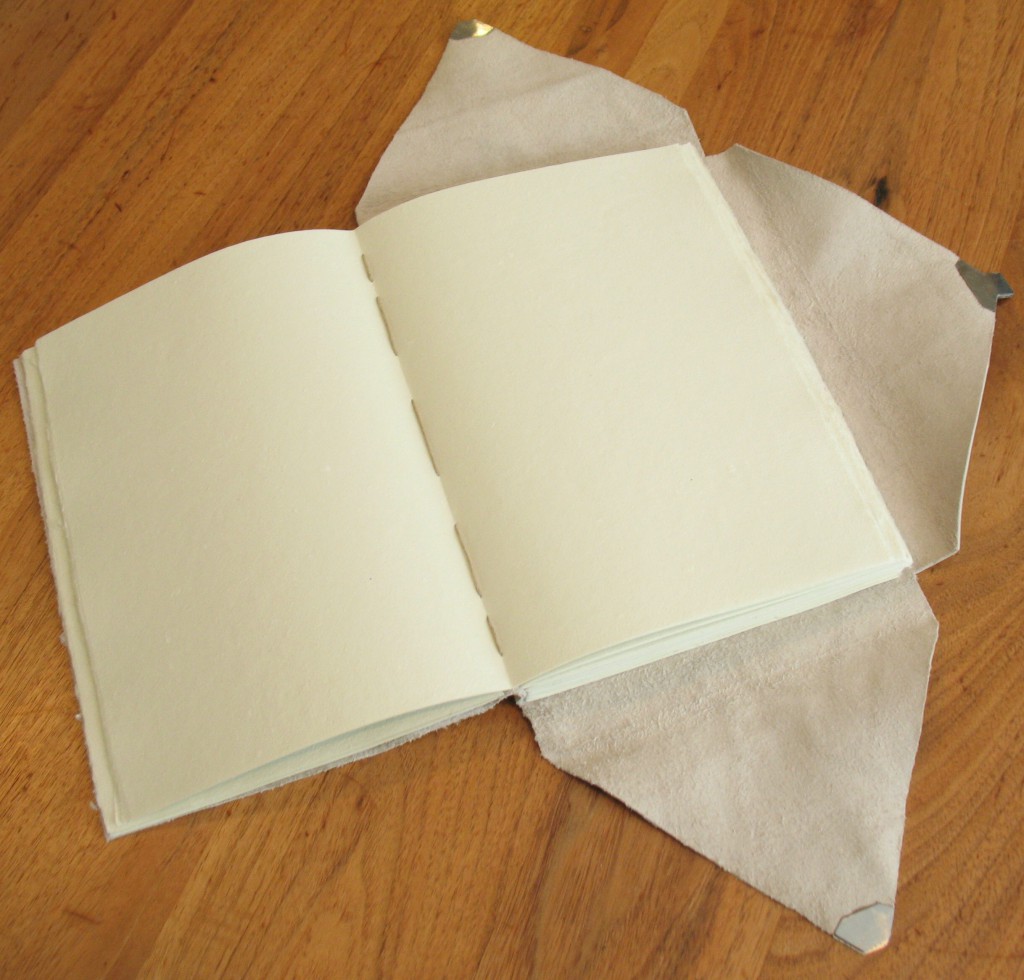

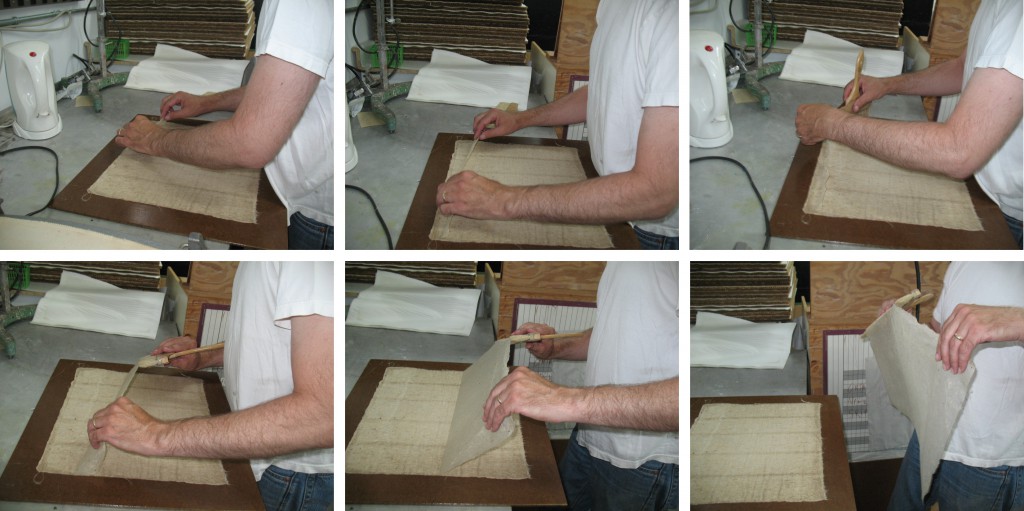

Here I am using the thread embedded near one edge of the post to lift the edge of the next sheet of paper. This is the smaller post and you can see it is resting on a (somewhat stained) Pellon couch.

This sequence show removal of one sheet from the larger post. After pulling the thread, I make sure the entire edge of the sheet is lifting cleanly, then I hold a brush in my right hand and use both hands to lift off the sheet, all the while watching for any tears starting.

Now I use the brush to smooth the sheet onto a drying board (in this case a sheet of 5/16″ polyethylene). There is an acquired knack to this in order to get the sheet laid down with no wrinkles.

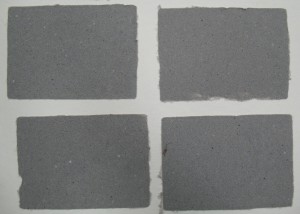

Altogether I think we had about 30 large sheets and 5 small ones, varying between excellent condition and (especially for the first sheets made) tatters. I’m beginning to see the common flaws in some of my sheets, to recognize them when the wet sheet is still on the su, and to see what I am doing wrong to cause them.