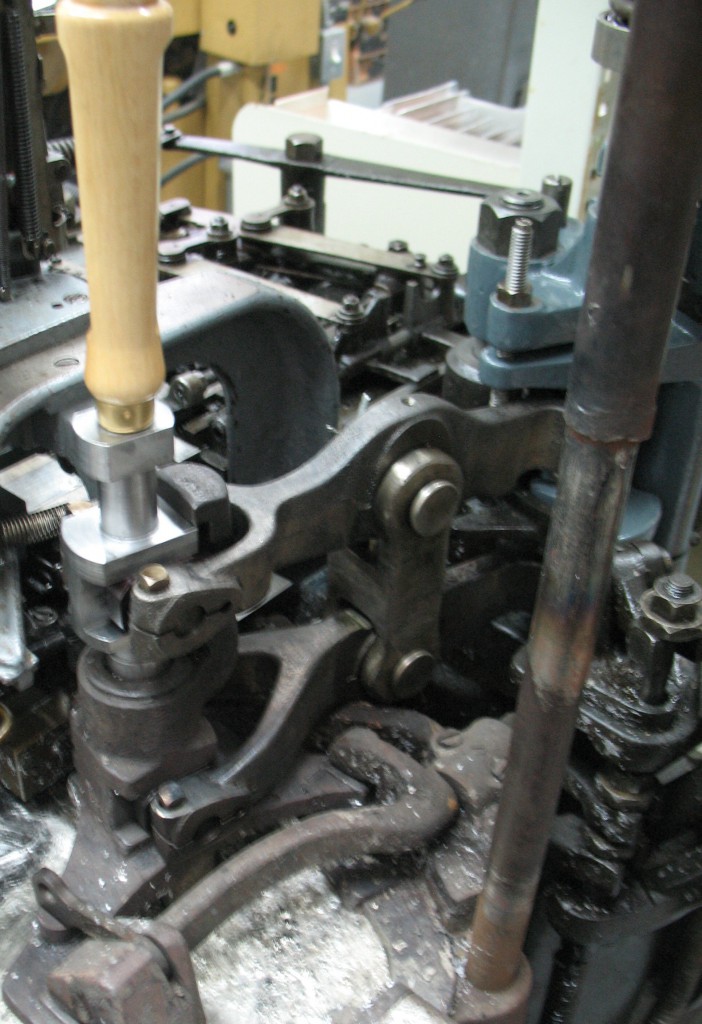

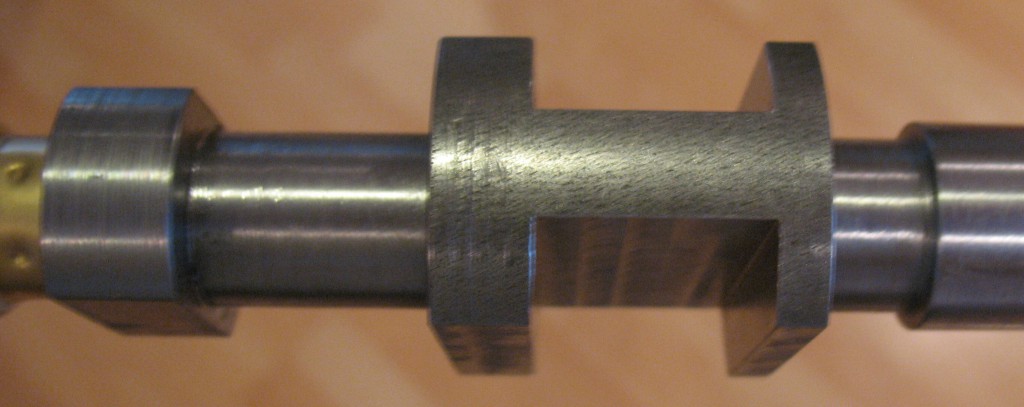

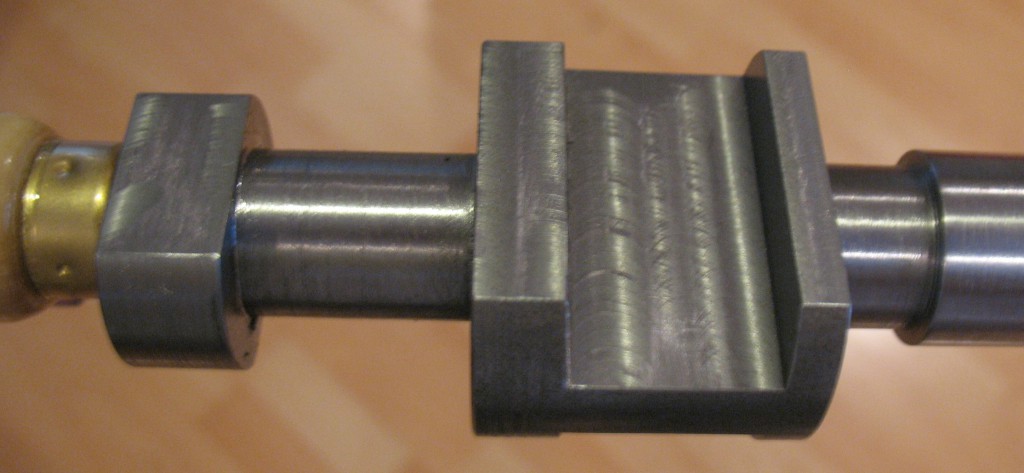

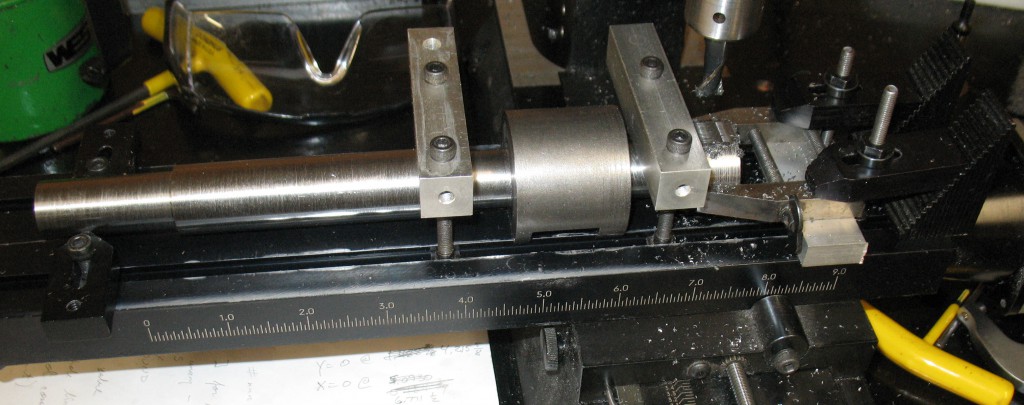

This is the culmination of a long three-pronged refitting of the pump on my Monotype composition caster. The three parts were disassembling, cleaning, and reassembling the pump head mechanism, refitting a pump latch mechanism scavenged from another caster, and making an extended-stroke pump piston rod to increase the volume capacity of the pump.

I reassembled the whole mechanism and adjusted it per manufacturer’s instructions. I found that the pump lever connecting link (a32H) not only has the obvious top/bottom asymmetry (the top contains a spring and plunger to pre-load the pivot) but it also asymmetric side-to-side. The way I had things assembled, the levers could not move low enough to engage the pump body and piston rod. After turning it around everything fit nicely.

I already had the pot fired up (so I could remove the pump body and replace the piston) so I proceeded to cast some type. After fiddling with some adjustments (since I did not have the appropriate reference cards at hand) I had it casting some nice, near-solid type.

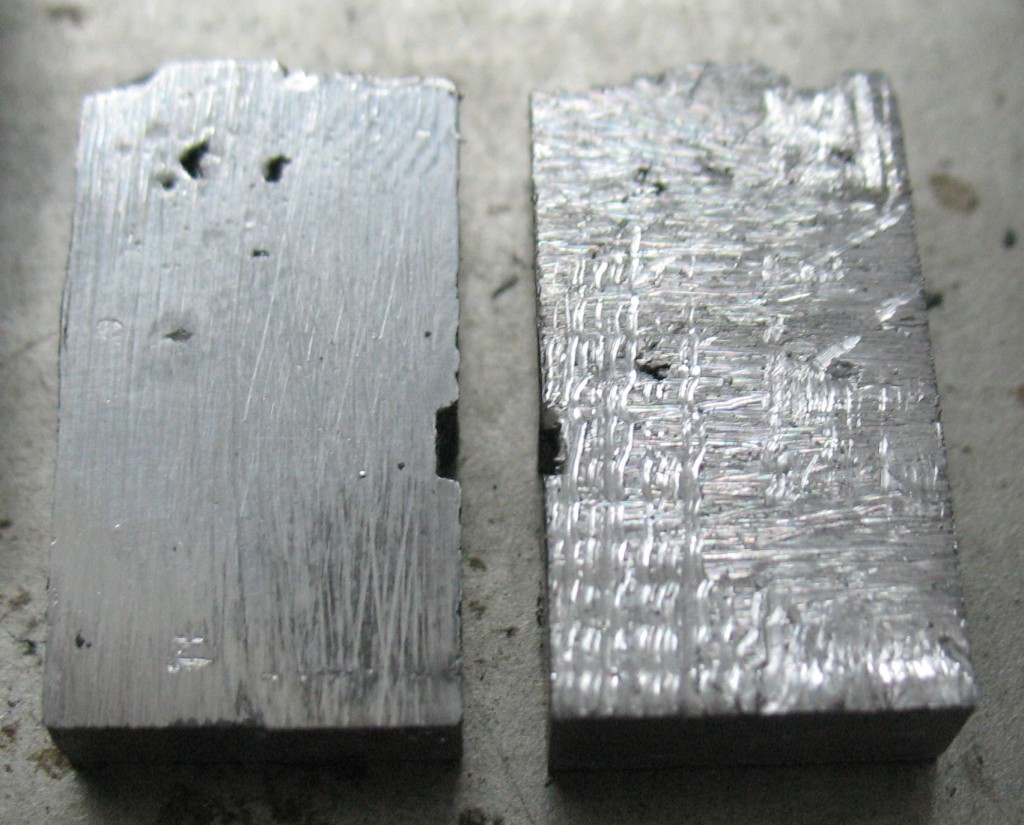

36-point Rockwell Antique capital N (31 points wide), cast using Linotype alloy. At the lower right is a type cut in half to see how solid it is.

A close-up of the type cut in half. The piece on the right is the raw sawn surface. On the left, filing the surface smooth reveals a few small bubbles near the face of the type, but not enough to weaken the face.

I was also weighing the individual types and had some that weighed more than the sectioned one, but to get that I had increased the pump pressure and was finding that many of the types had flash bordering on being an outright squirt from the pressure of the molten metal lifting the mat a bit. I am using an American bridge which has no provision for increasing the downward pressure on the mat.