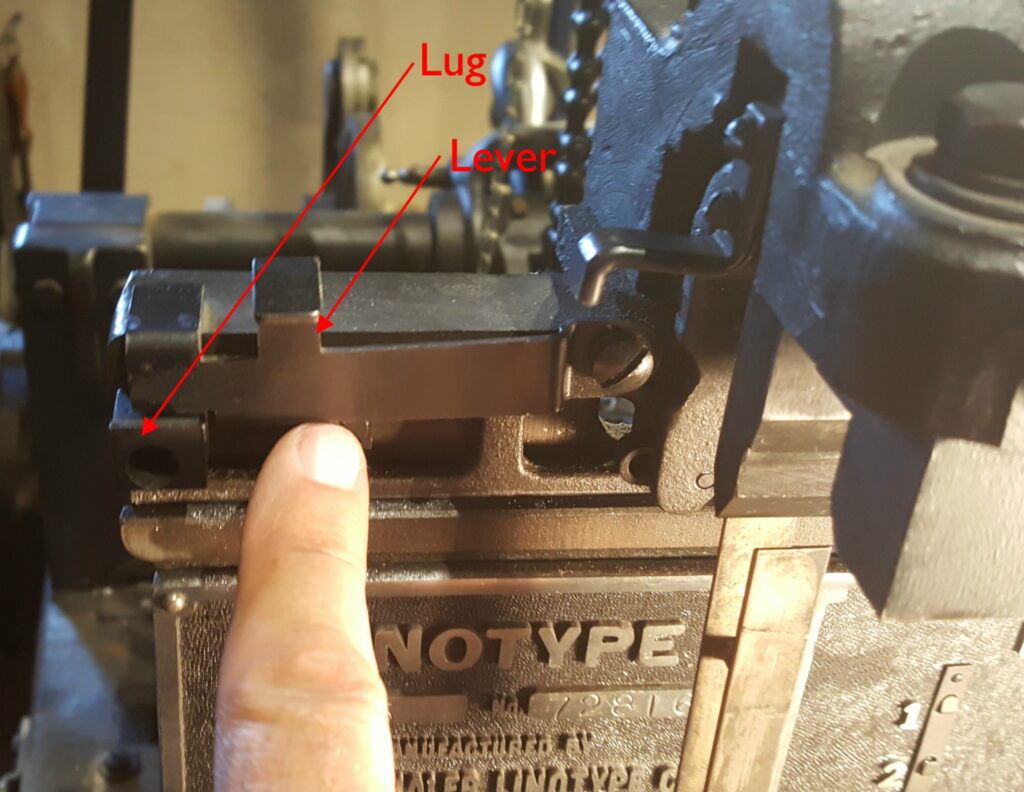

I recently cast several fonts of type in Monotype #329 Sans Serif Light. This included 12-point from composition matrices and 14-point from display matrices.

As with a few other Monotype faces, this one is available as display matrices in two different size designations, commonly known as 14#1 and 14#2. The latter is visibly larger than the former.

Not really understanding why these both exist, we opted to cast 14#1. On comparing the various fonts of type we observed that the 14#1 looked very much like 12 on 14, that is, 12-point type cast on a 14-point body.

Some digital photo manipulation of scans from the specimen book reveal what is going on. In all the following, samples of composition and display specimens have been superimposed, with one specimen in blue and the other in red (sorry, forgot which is which). Overlapped areas are black.

18 point large comp vs. 18 point display

So far, so good… The two 18-point variants match very closely. Note that the 18-point composition is only available if the caster is fitted for “large composition”.

14 point large comp vs. 14#2 display

Again, this is a close match, though not as close as with the 18-point, but it would appear that the 14#2 is the true 14-point version of the face.

12 point comp vs. 14#1 display

Now things go a little weird: It seems that 14#1 really is a 12-point font.

10 point comp vs. 12 point display

Just as with the (visually) 12-point fonts, there is a discrepancy in the sizing of the display font here.

One has to wonder why Monotype chose to call the last two display sizes 14- and 12-point when they are really 12- and 10-point. My suspicion is that because of the draft angle in the matrices, these faces cannot be cast on their proper body sizes because the beards of the type would project top and bottom. Such type would require hand finishing to remove the beards. To avoid this Monotype labeled them based on the body (mould) size that must be used, and used the #1 and #2 designations to differentiate the two sizes that cast on a 14-point body. The 14-point faces are not an exact match, so it could also be that the 14#1 just would not fit on a 12-point body, even with no beards, but then, why would they design a face that way?

Some day if I remember I’ll test this theory by casting some 14#1 on a display mould fitted for 12-point to see if the type itself fits but projecting beards are unavoidable. It should also be mentioned that there is, to my knowledge, no such thing as a 10-point display mould, so the 12-point mats could not practically be cast on their proper 10-point body. You could use a composition mould, but the nick would be on the wrong side of the type and getting proper alignment might be difficult.