This group of about 20 people runs a cooperative shared letterpress shop in Richmond Hill, just North of Toronto. Members have access to use the shop during daytime hours and there are a couple of keys available for after-hours access. We also hold meetings more or less every second Thursday evening from 7:30pm until around 9 or 10. Anyone is welcome to come to the meetings but because they aren’t perfectly regular it would be a good idea to e-mail one of the members a day ahead to ascertain if there is indeed a meeting. There is no formal structure to the meetings; they are more of an agreed-upon time slot when you can show up and expect to find other members there to talk to.

The shop occupies about 400 square feet in the basement of the Vanderburgh House, the balance of which houses the Richmond Hill Chamber of Commerce. It is the CoC’s office hours which control when you can visit the shop without a key, and the CoC’s desire to keep a lid on the number of keys floating around which limits the Guild to holding only two keys for after-hours access.

The Vanderburgh House is a building of some historic importance in Richmond Hill which was actually moved from its original location to its current address of 376 Church Street, at the corner of Weldrick Avenue, just a short block off Yonge Street.

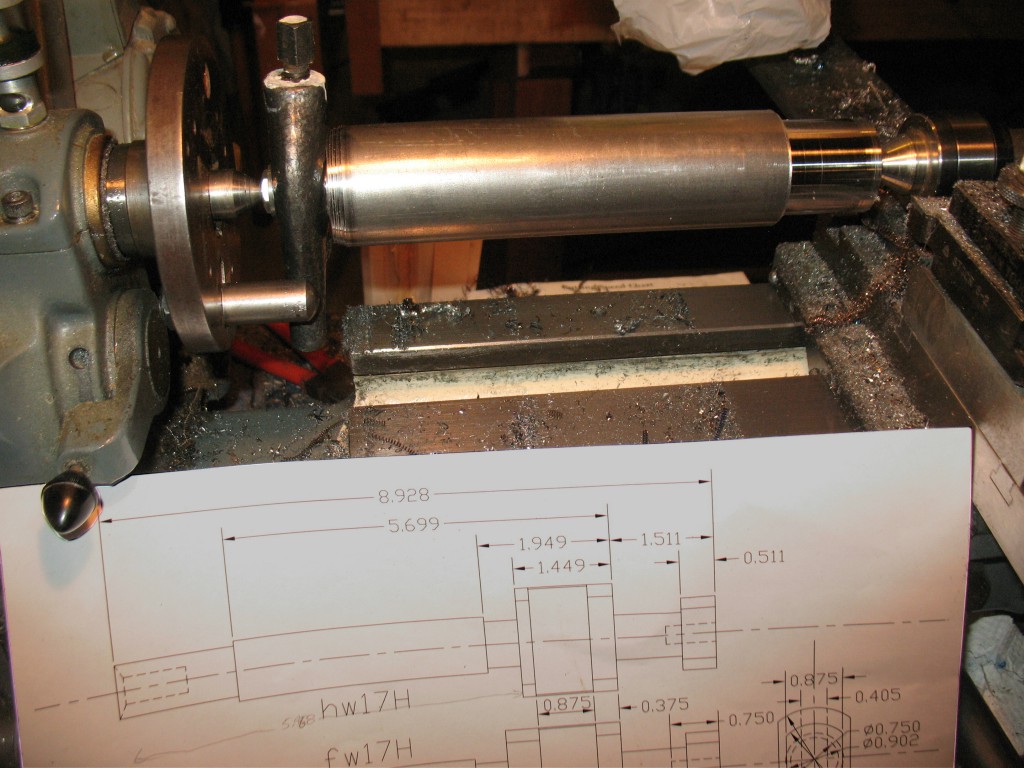

Equipment at the shop includes a Vandercook SP-15 proof press, a C&P Old Style 10×15 (I hope I have that right), and a tabletop Adana press. There are also a guillotine, a type saw, a 100-slot 12×18 galley cabinet, 6 cabinets of type along with all the odds & sods required for letterpress work: spacing, leading, chases, quoins, furniture, a small assortment of ink, etc.

There appears to be a meeting coming up this Thursday, May 16th, in case you want to drop in. If you want to find out about when other meetings are taking place, you should e-mail one of the members (the Guild does not have any Web presence of its own), including ourselves at info@papertrail.ca, Cam Knight, or Thomas Dannenberg.