Last Saturday I tried again to do a run of composition casting. At some point, the galley mechanism stopped working, and a very long line developed in the galley.

I stopped casting and looked for the cause of the problem. The justification was still taking place, but when the galley trip rod (a49D) was pushed forward by the justification mechanism it didn’t even touch the galley trip lever.

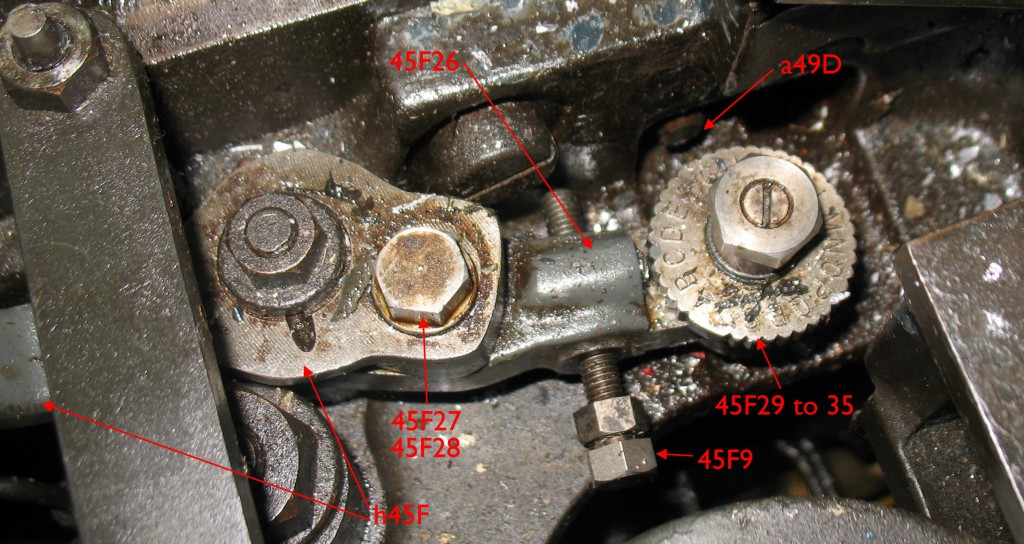

On the English casters, this trip lever (h45FF) has a graduated adjustable cam (45F29 through 35) to control how far the trip rod has to move before tripping the galley. This allows the setting to be adjusted to compensate for overthrow of the trip rod when the machine is running fast and a single justification is coded in the ribbon, and also allows the switch between using single and double justification to trip the galley. I couldn’t really understand how this could have gone out of adjustment so easily, but I reset the cam position so double justification would trip the galley again.

I started casting again, and the galley tripped properly this time, but partway through its cycle there was an unexpected clunk. At the next line end, the galley did nothing again even tough I saw the trip lever move.

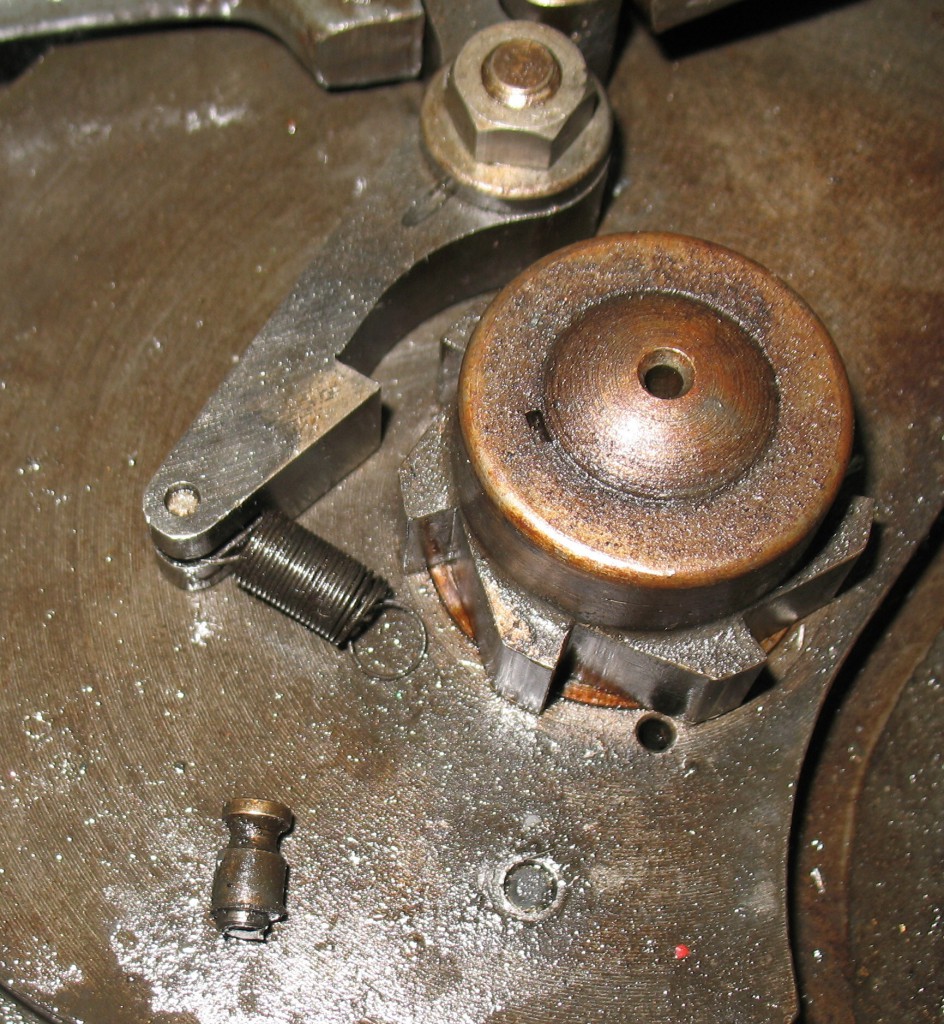

I stopped the machine right away and removed the tool tray to check the galley mechanism. This is what I found:

The post (14F6) that the pawl spring should attach to was snapped off. It seems that halfway through the galley cycle, the galley trip lever had caught this post and snapped it off. This implied that the trip lever was capable of swinging much too close to the axis of the galley cam, so the stop bolt (45F9) was also adjusted wrong.

It was only when I had a closer look at the trip lever and its adjusting cam that I realized the true cause of the original problem. The bolt (45F27) that locks the two pieces of the trip lever (h45F and 45F26) together had loosened and the two ends of the lever had swung out of their proper relative positions. You can actually see the clean spot where the washer should be. Because this had shifted the trip lever was able to swing in and catch on the spring post.

The American casters have a one-piece trip lever, and use an adjustment screw (along with a spacer that swings in & out for single- or double-justification galley trip) to accomplish what the fancy cam on the English machines does. The presence of this two-piece trip lever seems somewhat superfluous to the adjustments provided by the cam and stop bolt. Its only reason for being there seems to be so that the trip lever can be set so position A of the adjustment cam reliably trips the galley with single justification at low speeds. This ensures that the adjustment cam has enough range to work with double-justification galley trip at high speeds.

In any case I re-adjusted the trip lever based on the instructions in Monotype Composition Caster Manual (I will have to check this) because Casting Machine Adjustments only refers to the American-style trip lever. Position A of the cam now gives low-speed trip on single justification, and position N (I will have to check this too) gives low-speed trip on double justification. Since I am not using justification changes within the line I would probably not notice if the single justification that forms half of the line end is also tripping the lever due to the caster speed. I also tightened the locknut on the stop bolt, something which I neglected to do previously, as is clear in the first photo.

This left the job of replacing the post. I had good luck on two fronts there. I had a spare post which was easy to find because it was still in its place in the spare galley cam I have. I was also lucky in that the broken stub of the post was loose in its hole, so I could unscrew it by tapping on its just right using a small prick punch.

So because I didn’t analyze the original problem properly, I ended up breaking another part. I was fortunate in that replacing it was fairly easy, and even if I did not have a spare on hand I could have made a suitable replacement.

Besides this, I had other problems casting as well, although I also had a couple of improvements from the previous casting session. Details to follow.

Fixed a typo in the title. Clearly there is no spell checking there!