We received our Sigwalt Chicago No. 11 press with no chase so it has been sitting collecting dust for a while.

We received our Sigwalt Chicago No. 11 press with no chase so it has been sitting collecting dust for a while.

I recently cobbled together a chase from a scrap of the ¾″-thick high-density polyethylene (HDPE) sheet we use to make our moulds and deckles.

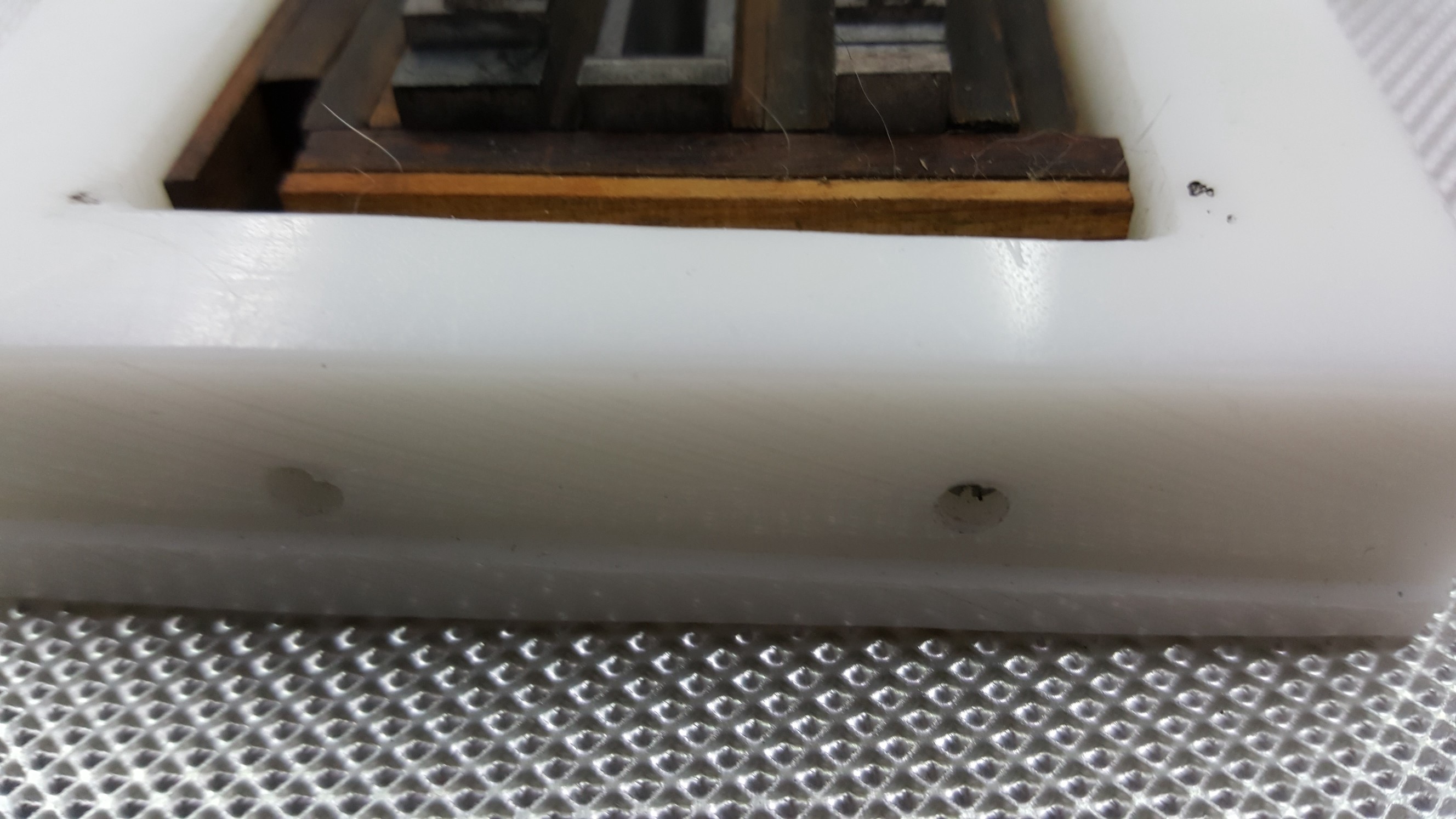

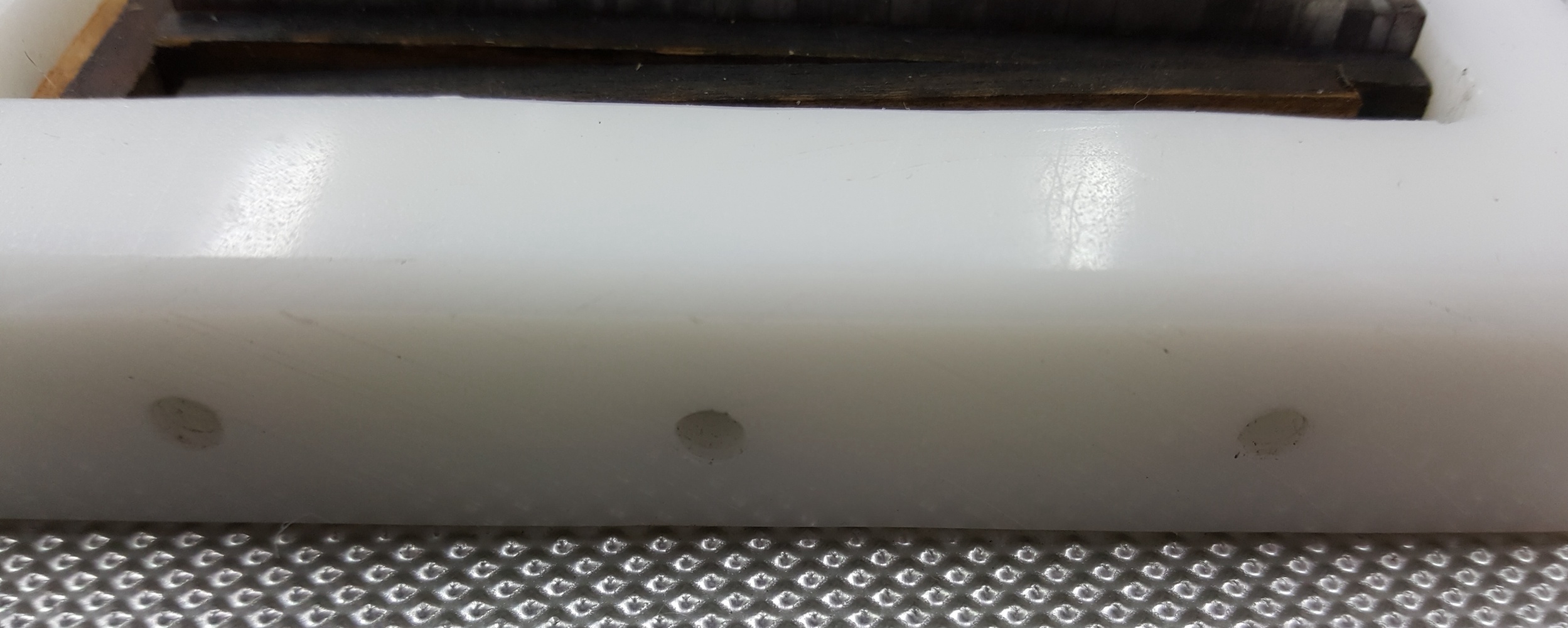

I cut the HDPE to a rectangle which fit closely between the rails of the press, then shaved off a bit on each side leaving a small wedge to engage the chase retainer lugs on either side of the bed. I cut the chase opening using my sabre saw, with a drilled hole to start the cut, and filed the edges to the desired shape (more or less). I drilled some holes on two sides and tapped them #8-32 to take setscrews to lock in the type.

Locking screws in the side of the chase. Note also the wedge-shaped ridge which engages in the lugs on either side of the press bed.

To test it, I locked in three lines of standing type I had waiting to be dissed (the title lines from a Wayzgoose Anthology submission from four years ago). After some fiddling with packing and the press bed adjustments I got a half-decent print out of it. The rollers on this press seem really hard (Shore A45/OO90) for the strength of the roller saddle springs, and things ended up a bit over-inked.

This press has a small foot so it really needs to be attached to a tabletop or larger base to avoid tipping when operating it. A bigger base plate and new ink rollers are the next items to be addressed for this press.

Because I hand-shaped the opening, one end of it is a bit wonky so I put the setscrews in that end. The other screws ended up on the bottom of the chase purely by chance. I didn’t have the correct screw size handy so I made my own, and the slot in the head (cut with a hacksaw) is a bit too narrow to accept the screwdriver tip properly. Also, the screws have to be recessed so it takes a tiny screwdriver to tighten them. I think I will re-drill and re-tap the holes to accept the same screw size as those on the chase of our Kelsey press (which I think is ¼″-20) so I can use the same screwdriver that I use for the Kelsey.

This gives me a starting point for making a chase out of metal. The HDPE material is very forgiving so I didn’t need to worry too much about proper engagement of the retainer lugs. The lugs on my press bed do not match each other so for a metal chase there would be manual fitting on both sides. I can think of several ways of forming a metal chase:

- Joining four bars using mechanical fasteners

- Welding four sides together

- Bending one long bar at the corners and welding the rectangle closed

- Drilling a starting hole in a solid plate and using the sabre saw to rough out the hole

- Using a cutting torch to rough out the hole

- Cutting the hole out with my mill

A genuine chase seems to be about 5/16″ thick on the top and bottom, and 7/32″ thick on the sides, so welding four sides together might be the easiest way, as long as I can keep the sides from distorting.

Hey KP Martin! Any updates on your journey? I just picked up a sigwalt no. 11 myself, am Ontario based too! Would love to hear how the chase is coming along!

Belinda,

Nothing new to report. Some projects sort of happen at a snail’s pace here. We have a bunch of orders for moulds and deckles so I have to catch up on a backlog of production…

Hi,

I just bought a Sigwald No. 11 and it is missing the rollers and trucks. I am exploring buying several from a rubber roller company in Tampa, FL, if they have my size, but right now am guessing the sizes.

Could either of you take a few measurements of your rollers (length, diameter, and pass them on to help me get this thing workable again?

Thanks so much.

Mike,

Sorry it took so long to approve your comment and reply.

The rollers on my press have the following dimensions:

Core: ¼” diameter × 6¼” long

Roller: ¾” diameter × 4¼” long

Trucks: ¾” O.D. × ¼” I.D. × ⅜” wide

The trucks are free-wheeling on the core (no lugs).

The current rollers are translucent and I can see that the core was wrapped with cord before casting the rollers, a fairly common step to prevent the soft roller material from shifting on the core.

That being said, I’m not 100% certain that this press is a Sigwalt Chicago #11. There seem to be some details that look a bit different from the (fuzzy) picture I saw in an old Sigwalt catalog, but that could also be year-to-year variation in design.