We’re running low on the stock of some of our pigments. As is often the case for us, we purchase such products so rarely that information from the last purchase is essentially useless. The supplier has almost certainty purged any record of our previous purchase and contact information, and frequently the supplier has undergone some sort of reorganization, division sale to another company altogether, or policy change that makes reordering “another of the same” impossible.

Because of this, we have to reach out to our current slate of appropriate suppliers to see what they have to offer. In this case we would be looking for an aqueous-dispersed red pigment, colour index PR112. The colour index code only identifies the fundamental chemical nature of the pigment, and other factors (e.g. crystal structure) can have profound effects on the final result of applying the pigment.

As such, then, we have to obtain a sample of pigment from the supplier, and use it in test batches to see how it compares with our existing product. We can never expect a perfect match, but it has to be close enough that our customers only have to make minor adjustments if they want to reproduce a paper colour they’ve made before.

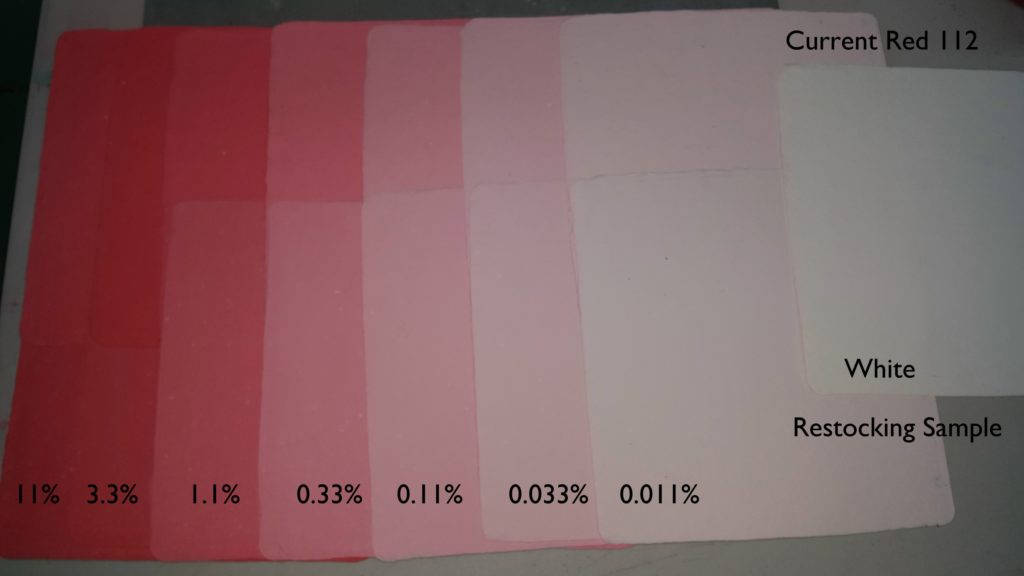

Here is an array of the test sheets from part of our run with R112:

The numbers across the bottom indicate the pigment dose relative to the dry pulp weight. They are actually a bit of a fudge, since we measure the pulp by weight and the pigment by volume, but by assuming the pigment weight 1g per ml, you can express the dose as a percentage.

One thing to note is that the 11% and 3.3% sheets are pretty much equally dark. This is because I was relying on the sizing (applied at the usual recommended rate of 15ml/kg i.e. “1.5%”) to act as a retention agent, and the heavy pigment doses overwhelmed that retention ability.

Although it doesn’t show so well in the photo—I should have used better lighting—but most of the sheets in the upper row are visibly darker than their mate in the lower row. To get objective data, I scanned each sample sheet on my flatbed scanner (with a white frame to help prevent auto-exposure issues) and used the histogram feature of my photo-edit program to evaluate the lightness. In selecting where to take the histogram, I would use most of the area of the sheet but would exclude dark or light spots caused by dirt or knots of pulp that did not pick up the pigment. I only used the Green channel for this, since the Red channel would have been pretty much 100% reflective for all samples, and Blue is not as complementary to the pigment as Green is.

Analyzing the data indicated that our current pigment stock was 1.7-2 times stronger than the new sample pigment, that is, one would have to use 1.7-2 times the amount of the new pigment to get the same colour. I ran another sample run with just the new pigment, using double the dose (0.022%, 0.066%, 0.22%, 0.66%, etc) and have found the results to be very close matches to the samples with half the dose of our current pigment.

Thus it appears that if we were to go forward with this product (and we don’t seem to have many alternatives), we would have to recommend using 1.7 to 2 times the amount of pigment to obtain the same results as with our previous pigment.

Between the need to use more pigment, and the inevitable higher prices of any new stock, we hope this doesn’t result in too much sticker shock for our customers.

Leave a Reply