The two press-fit parts that I probably should never have disassembled on my Monotype caster pump head are now back together again.

As mentioned in my previous post I had already reassembled the Pump Body Spring Rod 31H1 and its crosshead 31H2 and nut. I put this assembly into its sleeve (a31H11) and collar stop (31H16), and slid the whole thing into its proper place on the caster. Without its spring, the part would stay in place by itself. I also installed the Stop Post (31H8) to act as a guide for positioning the other crosshead.

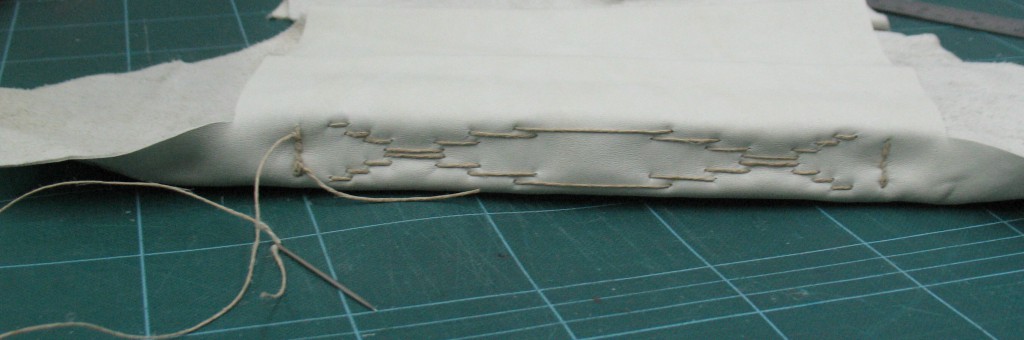

Then I slid the piston operating rod (19H) into its hole. It was a snug fit through the lower crossblock (19H1) which required pounding with a rubber mallet. I had the hole for the taper pin roughly lined up so I could visually verify that I had the rod at the correct height. Then I locked two nuts against each other on the top of the rod and use this to rotate the rod until I could insert the taper pin and tap it home.

This allowed me to install the upper crosshead (19H3) using the Stop Post as a guide to its orientation. As with the other upper crossblock, this one went on by striking it with a rubber mallet, then using the nut to draw it home.

Things then had to come apart again, for painting and installation of other parts. I removed the taper pin, and found that the piston operating rod could be removed from the lower crossblock by rotating the machine’s drive shaft until the rod rose to its uppermost position, placing a spacer under the crosshead, and rotating the drive shaft back to where the pump would be idle. There was enough force available for this to draw the rod partway out of the lower crossblock. This process was repeated several times using taller and taller spacers until the rod was free of the crossblock.

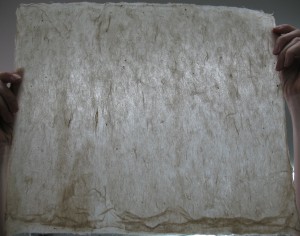

Both rods with crossblocks installed are now waiting for their paint job.