This weekend was our Rural Routes Studio Tour, during which I was demonstrating paper marbling. I spent quite a bit of time describing what I was doing, warning people to keep out of the spatter zone, and (when there were no visitors) sitting down to take a break. Despite this we (Lily and I) made 31 full-sized (18×24″ grain short) marbled sheets and 10 half-sheets (12×18″), along with two pieces of marbled fabric.

Two pieces of cotton 22×27″ that have been marbled. They still need to be rinsed to remove the residue of the marbling size which by then had become quite dirty with paint residue.

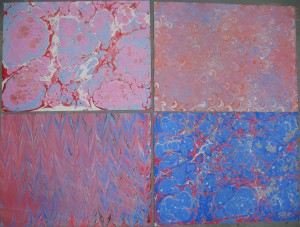

Two more marbled 12×18″ handmade sheets, and three 18×24″ sheets of commercially-made paper. Lily did the marbling for all of these except the upper-left one.

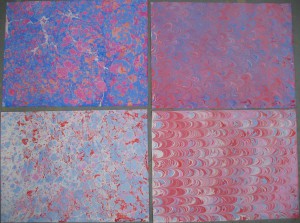

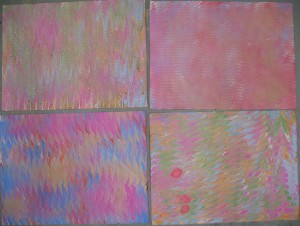

The rest of these are all on commercially-made 18×24″ paper.

These (and many more from previous marbling sessions) are all available for sale at our normal prices for marbled paper: $6.00 for the 18×24″ commercial paper, $7.00 for the 12×18″ handmade paper. We have some photos of other sizes in a previous blog post.

If you are interested in an introduction to paper marbling, there is still room in our marbling workshop next weekend (November 9th 2013).