The new spring rod might be a simple part to make, except that one can’t turn a 24″-long part on a 7×20″ lathe.

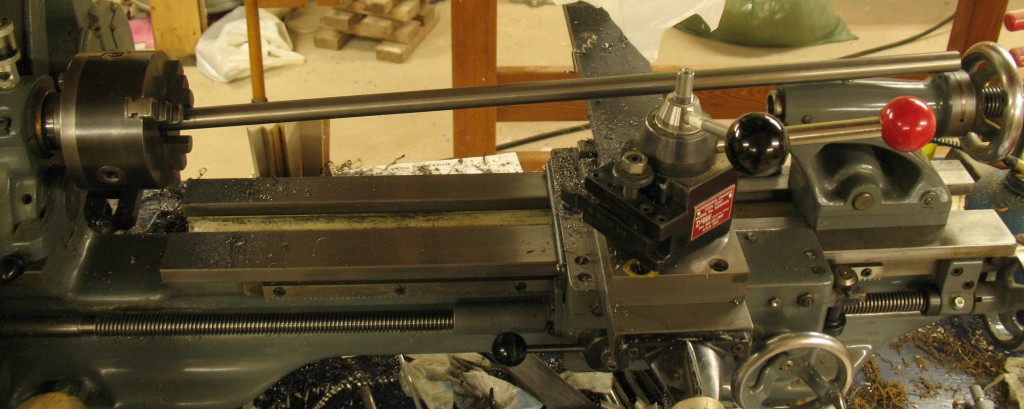

I thought the new spring rod I have to make for my Monotype pump would be relatively easy to do, after all, it is just a length of 5/8″ round rod threaded at both ends. The problem is that my Myford ML7 lathe bed is too short to hold the part, and the spindle bore is too small to allow the rod to pass through.

So now I have to come up with another way to do it. One way is to find someone with a larger lathe who will let me use it. Another possibility is to use the CNC capabilities of my mill to shape the ends of the rod. I will have to ponder the possibilities for a few days.

In the meantime I now have a Loctite Form-A-Thread kit for repairing stripped threads, and I will see if I can use it to improve the tapped holes in the pump latch.

Leave a Reply